I'm building a homemade boiler

- Thread starter warno

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

So progress has slowed a little the past few days. Another project came up that has taken priority. But I do have my shed siding on order, it should be in next week. And the roof frame pieces made at work.

I have a question on my shed build though. What problems will I face if I don't insulate the inside of my shed? My budget is getting streched pretty thin on my install and the spray foam that I wanted will pretty much kill it the rest of the way.

So, if my boiler itself is fully insulated, R15 front and back R30 top, bottom, and sides, will I need to insulate the shed this winter or can it wait?

I have a question on my shed build though. What problems will I face if I don't insulate the inside of my shed? My budget is getting streched pretty thin on my install and the spray foam that I wanted will pretty much kill it the rest of the way.

So, if my boiler itself is fully insulated, R15 front and back R30 top, bottom, and sides, will I need to insulate the shed this winter or can it wait?

OH_Varmntr

Burning Hunk

I would say it can wait, but you'll obviously lose a bit more heat than if the shed it sets in were fully insulated as well.

My Central Boiler has an enclosure built around it and is not insulated, only the woodburner is.

Another thing that matters is how much wind the shed will be exposed to. Wind whipping through the seams will accelerate heat loss from inside the shed.

My Central Boiler has an enclosure built around it and is not insulated, only the woodburner is.

Another thing that matters is how much wind the shed will be exposed to. Wind whipping through the seams will accelerate heat loss from inside the shed.

That's what I was assuming I just thought I'd ask to make sure. Thank you.

My other project is done so now I can work on this project again. This morning I put a second coat of paint on the boiler and doors. And started wiring my control box. I'll get pics of the boiler when it's back together.

This box will be mounted in the back of the boiler shed. I wish I would have picked up a bigger box for my controls. This one will do but it's filling up fast. I still have a few things to wire in here yet but here's how it looks right now.

This switch is in unison with my float switch in the water jacket. If the float switch reads "low water" it will shut off my fan and my circulater pump so it doesn't start sucking air into the lines.

Here's my other control box. This one will be mounted in the front of the shed. The indicator lights are green for "good water level", and red for "low water/system off". The switch is to bypass the aquastat control on the blower fan when loading wood.

This box will be mounted in the back of the boiler shed. I wish I would have picked up a bigger box for my controls. This one will do but it's filling up fast. I still have a few things to wire in here yet but here's how it looks right now.

This switch is in unison with my float switch in the water jacket. If the float switch reads "low water" it will shut off my fan and my circulater pump so it doesn't start sucking air into the lines.

Here's my other control box. This one will be mounted in the front of the shed. The indicator lights are green for "good water level", and red for "low water/system off". The switch is to bypass the aquastat control on the blower fan when loading wood.

OH_Varmntr

Burning Hunk

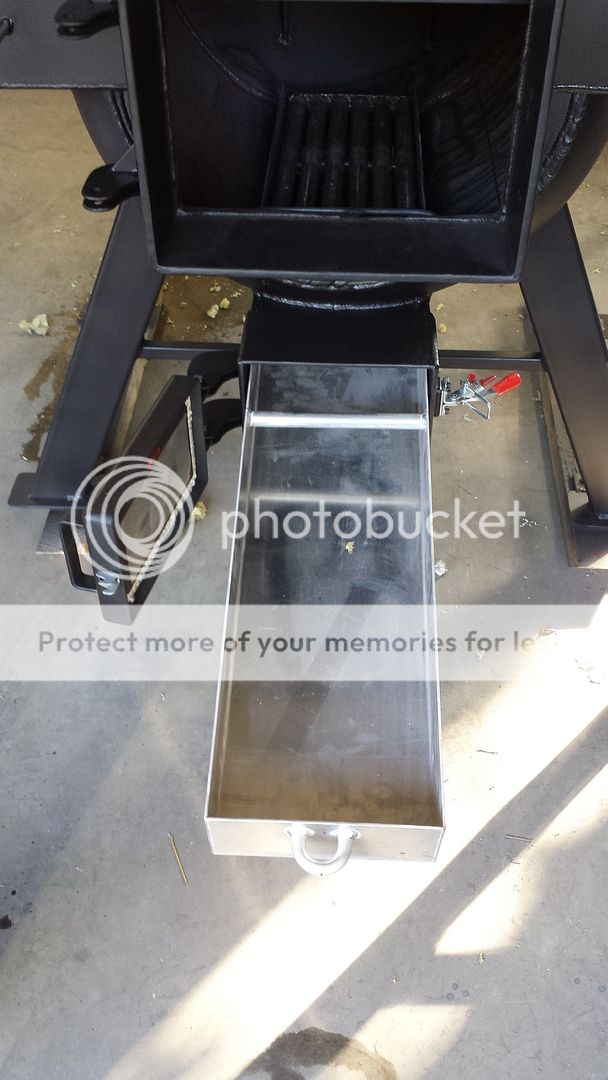

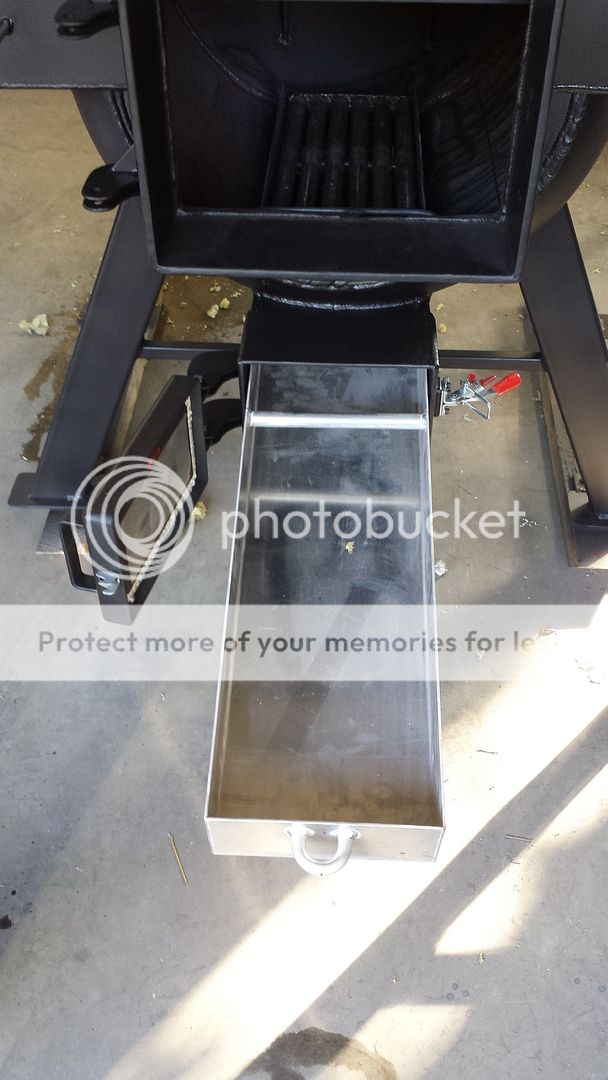

I've started putting things back together. The 3 clean out doors are on, valves put in place, blower fan mounted, sensor well installed, float switch installed, and the shed frame is going home with me today from work.

I picked up my shed siding the other day. So hopefully this weekend I can start putting that on.

I also tossed in my ash pan and my fire grate.

I picked up my shed siding the other day. So hopefully this weekend I can start putting that on.

I also tossed in my ash pan and my fire grate.

I haven't been taking many pics lately but things are getting done. I've got some more wiring done, almost ready to pour my refractory in the fire box, i'm hoping to get the shed siding on this weekend. Then I will get the shed insulation sprayed in. The shed doors are painted to match siding.

Just a few pics of progress.

The front insulation retainer.

The rear retainer didn't turn out quite as nice as I'd hoped but it's holding the stuff on there. I had interference issues with the valves so I had to change things up.

Shed door paint job.

Just a few pics of progress.

The front insulation retainer.

The rear retainer didn't turn out quite as nice as I'd hoped but it's holding the stuff on there. I had interference issues with the valves so I had to change things up.

Shed door paint job.

BoilerMan

Minister of Fire

The shed frame is on the pad and anchored down. Should be doing siding tomorrow morning. I have also started building my chimney flashing back at work.

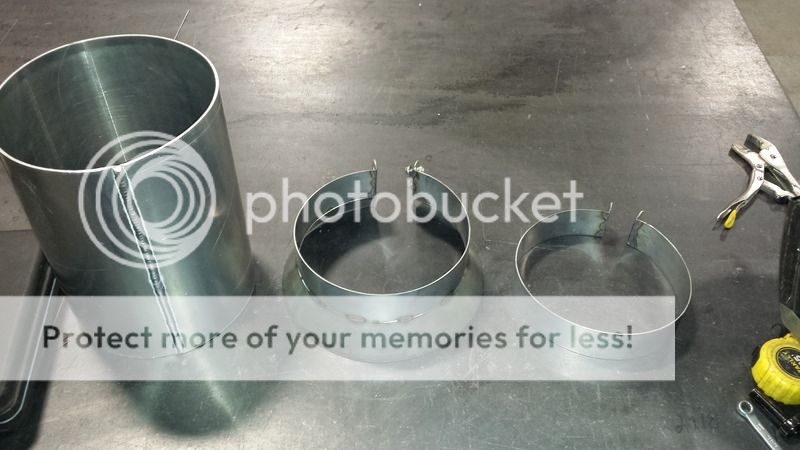

The chimney flashing. I rolled a piece of aluminum into a cylinder then welded the seam. I need to weld on the mounting plate for the cylinder yet. The chimney will pass through the cylinder out the roof. I have also rolled the stainless pieces into collars for the rain cover over the aluminum cylinder. I will weld tabs on the stainless pieces to bolt them tight to the chimney sections.

The chimney flashing. I rolled a piece of aluminum into a cylinder then welded the seam. I need to weld on the mounting plate for the cylinder yet. The chimney will pass through the cylinder out the roof. I have also rolled the stainless pieces into collars for the rain cover over the aluminum cylinder. I will weld tabs on the stainless pieces to bolt them tight to the chimney sections.

jatoxico

Minister of Fire

Z33

Burning Hunk

Looks like its all coming together! Still on track for Halloween?

Are you spray foaming the inside your self or contracting it out?

Are you spray foaming the inside your self or contracting it out?

I've kinda shot Halloween in the butt. I don't think it's doable with the amount left. Once I get the shed foamed and boiler in it things will pick up but I still have alot left.

Spray foaming was cheaper to pay someone else for it. Somebody local does it so I called them and got a pretty good price.

Spray foaming was cheaper to pay someone else for it. Somebody local does it so I called them and got a pretty good price.

Last edited:

Had my buddy come over with the skid loader to set the boiler in the shed. It fit but it's tight. I will need to get the roof done the rest of the way and get the chimney flashing and access panel done before I can foam the inside. Then off comes the front wall, again, and out the goes the boiler for room to foam the shed walls.

Last edited:

So quick question here. My boiler is sitting in the shed, shed is not insulated yet, boiler has insulation on front and back but not sides or top. I have 1 piece of 3 feet long class A chimney on the boiler with a bucket on top of it. Is it possible that condensation is building up inside the chimney section just from temperature changes from night to day? There was some water in my HX right under the chimney.

Last edited:

OH_Varmntr

Burning Hunk

OH_Varmntr

Burning Hunk

It should, yes. But so should filling the water jacket. It will insulate the firebox as well when you're not burning.

hoverwheel

Burning Hunk

I've been following this thread for reasons of envy and finally have a question. Is it common to add telemetry to a boiler like this? To remotely monitor temps, water flow, etc.

Did you run wire for that or would it commonly be done over wifi?

Did you run wire for that or would it commonly be done over wifi?

As of now my setup doesn't have any remote read outs. To see what's going on I will have to open the shed door and check my aquastat. I plan in the future to run some remote sensors into my garage so I don't always have to open the back door of the boiler shed to check temps of things. I believe any remote readings that are added to any boiler system (especially homemade) are up to whatever the owner wants.

- Status

- Not open for further replies.

Similar threads

- Replies

- 20

- Views

- 861

- Replies

- 10

- Views

- 1K

- Replies

- 2

- Views

- 277

- Replies

- 4

- Views

- 910