SmokeyTheBear

Minister of Fire

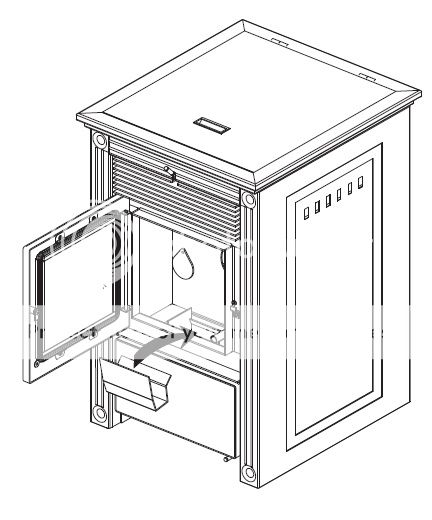

This stove does have clean outs. I cleaned those out too. I'll try the leaf blower trick to see if I can get more ash out.

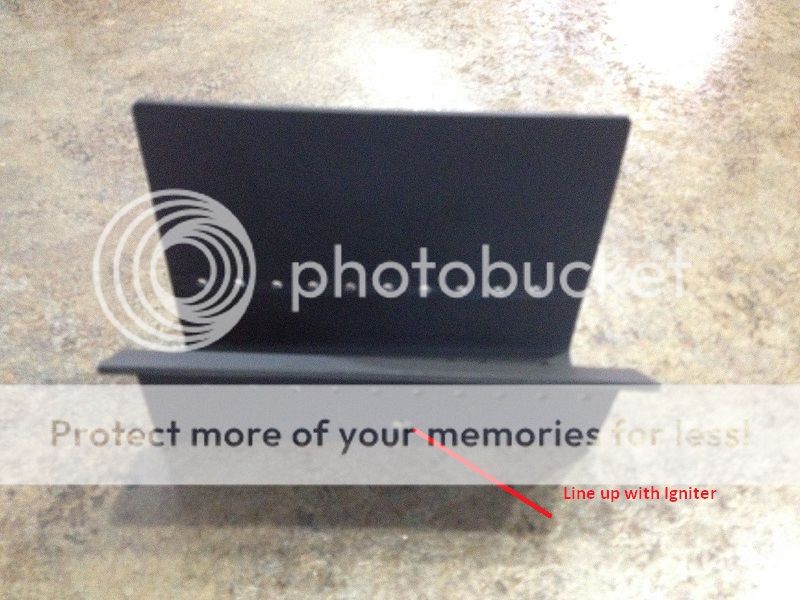

I had the local "stove experts" here last week to install the igniter and clean the stove. Needless to say he didn't do a great job. And he told my wife "tell your husband he'll never get it to ignite, the Bosca's don't work". Now I'm even more determined to get it working.

Get up and above those clean-outs and around and through the heat exchangers. From those clean-outs towards the center of the stove behind the firebox wall. If that rear firebox wall is steel and not cast iron a few whacks with a hammer on a piece of wood against that wall will loosen up crap stuck behind it.

Last edited: