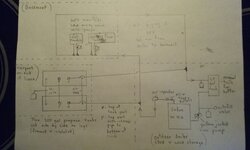

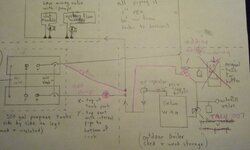

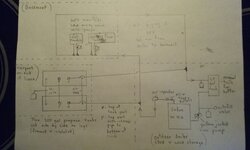

Hello, new member here. Have been reading the stickeys and older threads but have questions. I have a seton w90 I started using 5 yrs ago. 1st year terrible but learned quickly. Last year I was able to locate 2 500 gal propane tanks for storage. I cut into the existing lines between the boiler shed and basement and using sharkbites I T'd them in as the attachment shows. Last year I also changed the main circ pump to a yellow jacket and tried the dif T option. ( ended up using constant pump since the boiler would overheat when trying to get 180deg loop temp). Anyway I have the tank access open and was wondering if there are any suggestions on how to improve storage temp. I know now that the current piping is not optimal since I used a pipe from the top fitting to reach the tank bottom ( at least I read this gives poor stratification). Maybe next year I could mount one over the other and use the bottom fittings to get the best flow. Looking for the best way to get storage water through the boiler and up to temp. I have the original circ pump (taco 007) and thought about putting it back in as the main circ pump and somehow using the yellow jacket to get better flow through storage. All last year I never felt the storage temp was high enough. I am able to get the seton to burn cleanly and make hot water but feel the storage is not getting hot enough.

I currently have a calefi 280 series temp valve on order. I will add it in for boiler protection. Just took all the covers off and cleaned the heat exchanger (annual) very little creosote compared to previous years. Lot of grey flakey material on tubes but no creosote clogging the tubes. yea storage tanks.

Thanks for reading, Craig

I currently have a calefi 280 series temp valve on order. I will add it in for boiler protection. Just took all the covers off and cleaned the heat exchanger (annual) very little creosote compared to previous years. Lot of grey flakey material on tubes but no creosote clogging the tubes. yea storage tanks.

Thanks for reading, Craig