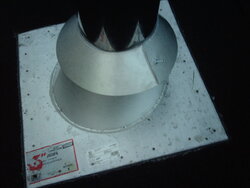

Two weeks i noticed water on top of the stove and a rust ring around the stove pipe collar going into the stove. This weekend while it was raining i sat and watched water drip at a pretty good pace right down the stove pipe from the ceiling. When i installed this i had put 2 rings of silicon around the flashing to seal it to the rolled roof, then a bead along all 4 edges and a dab on all the nail heads and a bead around the storm collar. Thought i did a good job but apparently not. Im going to go up today to use roofing cement to seal along the edges again and hit the nail heads as i noticed the silcon really didnt bond well on some of those. Anything im missing? It's got to be that flashing right? Do i need to be worried about the rust now on my stove?