I've been reading here for a good while like a lot of you. Trying to gets system down on paper and appreciate all the knowledge here. First thing I knew I would need was storage so I purchased an anhydrous ammonia tank that came up for sale thinking I would use it. Now the other day I found 2 scrap 605 gal LP tanks for 80 bucks apiece couldn't pass them up so need some advice on how to mount them vertically if I end up using them. Anyway it looks like there's pros and cons to both. The ammonia tank has a baffle and would need yo be horizontal in my case, the lp tanks vertical but a bear cat to weld on. I dunno what to do?

vertical storage mounting?

- Thread starter plumedic

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

maple1

Minister of Fire

JP11

Minister of Fire

You got the tanks so cheap.. spend a little money to have them welded on. I had a pro shop make a 'foot ring' and put in all the ports where i wanted them. Top, Bottom, and 4 on the sides, 2 at the top of the flat sides, and two at the bottom.

Cost a few hundred bucks.. but I was glad I didn't even attempt to mess with them.

JP

Cost a few hundred bucks.. but I was glad I didn't even attempt to mess with them.

JP

Tennman

Minister of Fire

We welded four 3"x3"x 1/4" angles to the sides of our 500 gal propane tanks (ends of the angle legs against the tank). I can give you the length of the leg welded to the tank and the weld fillet size if you're interested. I was going to weld a 3"x3" foot to the bottom of the legs, but our concrete is very thick there so decided is was unnecessary and sure enough was. I also welded a long 1 1/2" nipple that is parallel to the floor into the bottom dome to keep the tank height as short as possible to fit in our 10' ceiling height and provide ~2-3" of insulation on the very bottom (the tank peaks are installed between the ceiling joists. Besides the weld length for safety, it's best to create a flat surface so the ends of the legs form a plane or are all the same length so the tank is vertical. If minor shimming is necessary no big deal. Perfectly flat concrete is rare. BTW, "I" didn't weld anything... I provided the design sketches. Leak check all fitting welds with soapy water. You'll probably find some pin holes. If you want more details PM or ask here. The legs for vertical tanks are a big safety issue that can't be considered lightly.

JP11

Minister of Fire

Found a few pics..'ring' welded around the tank edge. said it spread the weight out over the surface area better than legs could. pic is sideways.. you get the idea.

JP

JP

Coal Reaper

Minister of Fire

I did mine a little different. Built more of a frame for the bottom so corner to corner of the legs were further apart. Any method get the job done. They way i rigged things up to winch them, i think the frame is stronger than just legs. Not a big deal if you are setting them with a machine. https://www.hearth.com/talk/threads/sending-500-gallon-tanks-verticle.107273/

Tennman

Minister of Fire

FYI. We needed a plan for the forklift to carry the tanks into the barn, rotate the tanks to clear the door opening, and handle them with foam applied. We welded two 3"x3"x1/4" angles to the sides slightly above the CG so they would hang from the forks yet allow us to pivot them in the closed space. You see one of those angles sticking out of the foam in the pic below. Regardless of the base design, we'd have needed these for handling since we didn't foam in place. We took the tanks to the foamer vs having the foamer come to us. Worked fine. Point is these things are dangerous heavy.Think how you're going to safely handle them inside the space. It was plenty tricky with a 10 Ton forklift and four guys.

woodsmaster

Minister of Fire

if you haven't allready put your holes in, I'd put one in the very bottom of the dome and one at the very top of the dome on the other end. That way you use the whole tank.

I was thinking about that wood master dropping a pipe in the center and welding the end shut and putting holes in the sides of the pipe to defuse the water. Maybe not necessary, but what's the good way to pipe it to get even flow through both tanks ? I'm sure there's probably a thread on it if I'd start digging.

woodsmaster

Minister of Fire

No need for a defuser , you don't want to mix the tanks. Keep the hot water on top and it will gradually make it to the bottom as the tanks charge just use fat pipes. i plumbed mine parallel. to do that you need the exact same plumbing to both tanks. same length, size pipe. make sure the horizontal runs are level etc. if one side has a level pipe and one side has a pipe running up or down hill they wont charge, un-charge at the same rate.I was thinking about that wood master dropping a pipe in the center and welding the end shut and putting holes in the sides of the pipe to defuse the water. Maybe not necessary, but what's the good way to pipe it to get even flow through both tanks ? I'm sure there's probably a thread on it if I'd start digging.

maple1

Minister of Fire

Also don't think a diffuser is necessary here.

My two stacked horizontal tanks stratify just great. 1-1/4" pipes. In at the top of the end of the top one, out at the bottom of the end of the bottom one (same end each tank), the tanks are connected bottom of top tank to top of bottom tank at the opposite end. Just 'common sense' flow balancing. When charging I get solid stratification - both my temp guages stay cold (120-130) then go hot (160 first pass) quickly as the stratification layer lowers. So I've got 600 gallons with only 6' or so of verticallity.

My two stacked horizontal tanks stratify just great. 1-1/4" pipes. In at the top of the end of the top one, out at the bottom of the end of the bottom one (same end each tank), the tanks are connected bottom of top tank to top of bottom tank at the opposite end. Just 'common sense' flow balancing. When charging I get solid stratification - both my temp guages stay cold (120-130) then go hot (160 first pass) quickly as the stratification layer lowers. So I've got 600 gallons with only 6' or so of verticallity.

Bob Rohr

Minister of Fire

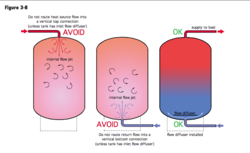

The use of a diffuser tube could be determined by the flow rate or velocity. Too much stiring of the tank breaks up the thermocline.

If you use side tank ports, just install a nipple that turns up or down to assure you circulate the entire tank.

If you use side tank ports, just install a nipple that turns up or down to assure you circulate the entire tank.

Attachments

Coal Reaper

Minister of Fire

i used diffusers. i didnt want to be saying to myself "man, maybe i would stratify better had i put diffusers in..." for years to come.

additionally, i did not put my cold connection right at the bottom of the tanks. inevitably, there is likely to be rust scales in the tanks no matter how well you clean them out. i wanted a bit of dead space for that stuff to collect. (incorporate some wye-strainers into your plumbing as well) i welded nipples on an angle the reach into the domed end, but not quite to the bottom.

there will also be some minimal amount of heat transfer to the concrete under the tanks. if i were to do it again, i would put a sheet of HDPE between the concrete and tanks to act as a bit of an insulation barrier.

additionally, i did not put my cold connection right at the bottom of the tanks. inevitably, there is likely to be rust scales in the tanks no matter how well you clean them out. i wanted a bit of dead space for that stuff to collect. (incorporate some wye-strainers into your plumbing as well) i welded nipples on an angle the reach into the domed end, but not quite to the bottom.

there will also be some minimal amount of heat transfer to the concrete under the tanks. if i were to do it again, i would put a sheet of HDPE between the concrete and tanks to act as a bit of an insulation barrier.

Attachments

woodsmaster

Minister of Fire

If nothing else you want drains in the very bottom of the tank. When you fill a system the first time most chemical places recommend heating the system up a couple of times then draining and refilling before adding your chemicals. this gets out any flux, oils etc that may be in the system. Hard to get that out without drains / outlets in the bottom of the tanks. with a y strainer any rust, solder , etc. will be caught in it so no need for somewhere for it to settle to. My tanks stratify perfectly with no diffuser.

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 2K

- Replies

- 8

- Views

- 429

- Replies

- 5

- Views

- 420

- Replies

- 1

- Views

- 589