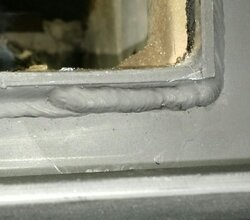

Hey all, have a 1 year old 28-3500 with a small 2" crack in the weld below the door flange (right side). A welder indeed verified and said the weld was too shallow there and he will grind the entire bottom and re-weld. He said it would be better than new. I am in contact with Englander and they seem to be willing to pay for the fix, although final approval has not been given. I know cracks in that area have happened on a few other stoves from fellow members before. I plan to add fire brick to that spot on either side once the repair is made. Thanks to this forum I heat with dry (<22%) wood and the stove has never been over fired. Probe therm has hit 1000 once or twice but only for a minute and the face of the unit has never been over 650. Any thoughts about this or suggestions are welcome.

Englander 28-3500 Crack

- Thread starter FaithfulWoodsman

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Highbeam

Minister of Fire

Yep, it opens up a bit when the stove is hot. I just wanted it fixed so it doesn't get worse.Is it that super fine hairline crack that is horizontal?

unfortunately I had to reduce the file size, but it's much more visible and pronounced in the original pic.

maple1

Minister of Fire

I really have no idea, but 650 on the front sounds a bit high to me.

Anybody else who runs an Englander measure their temps? And how? Might be variations in temp measuring methods & devices too.

Good luck, anyway.

Anybody else who runs an Englander measure their temps? And how? Might be variations in temp measuring methods & devices too.

Good luck, anyway.

Thanks. Tech from Englander said over fire is front face above 900 and burn zone 400-700. That seemed a bit high to me which is why I keep it 350-550. But has got to 650 a couple times. Would love to know what others keep theirs at.

Two Condar dials on the face and a probe 20" above the stove. Infared to spot check. Use em all cause mine hot spots like crazy.

lexybird

Minister of Fire

Never saw a crack on a 28-3500 before . I ran one for many years . I had it well over 650 multiple times and it never caused any issues aside from a warped baffle ( which they replaced for free)

Most say they run them hot without issue which is what puzzled me about mine. Oh well. Englander approved the fix. Welder coming out tomorrow. $170 for the job. Should I wait a day to fire it up or is the weld good once finished? No experience with welding.

I have heard of a couple of those that cracked around the door flange. I don't believe it is a widespread problem though.

A welder who knows what he is doing should be able to repair that with no further problems.

I have heard that ESW stands behind their products pretty well. Hopefully, in your case, they do. I have had a really good experience with mine. Plenty of heat if I run it properly. Probably uses more wood than the secondary burn stoves but I think it is one of the more efficient old school burners. Lexybird, among others on here, helped me out a lot with advice when I was getting started with mine. Hope it goes well for you.

A welder who knows what he is doing should be able to repair that with no further problems.

I have heard that ESW stands behind their products pretty well. Hopefully, in your case, they do. I have had a really good experience with mine. Plenty of heat if I run it properly. Probably uses more wood than the secondary burn stoves but I think it is one of the more efficient old school burners. Lexybird, among others on here, helped me out a lot with advice when I was getting started with mine. Hope it goes well for you.

I have heard of a couple of those that cracked around the door flange. I don't believe it is a widespread problem though.

A welder who knows what he is doing should be able to repair that with no further problems.

I have heard that ESW stands behind their products pretty well. Hopefully, in your case, they do. I have had a really good experience with mine. Plenty of heat if I run it properly. Probably uses more wood than the secondary burn stoves but I think it is one of the more efficient old school burners. Lexybird, among others on here, helped me out a lot with advice when I was getting started with mine. Hope it goes well for you.[/QUOTE]

Thanks. ESW has been great and is making it right. They have been a great company to work with, highly recommend. I learned a tremendous amount from this forum when I got mine. We love ours and I agree it can be a decent burner when used properly. My only concern is that I tend to not be able to shut it down as much as I'd like and still keep the heat up. Once a full load is going I leave the bottom knob 1-2 cogs open (1/16" crack), and the top slide 1/2 to 3/4 closed. This typically gets me 4 hours of "good" heat and another 2-3 of "so, so" heat. (dry wood <22%, well educated from this forum) I mostly burn 1 year ash and cherry. Hoping to get a little more heat from some 2 year red oak when it gets frigid. I did install a stove pipe damper this year and will experiment with that to try and get more heat out of the unit. Any suggestions are welcome.

A welder who knows what he is doing should be able to repair that with no further problems.

I have heard that ESW stands behind their products pretty well. Hopefully, in your case, they do. I have had a really good experience with mine. Plenty of heat if I run it properly. Probably uses more wood than the secondary burn stoves but I think it is one of the more efficient old school burners. Lexybird, among others on here, helped me out a lot with advice when I was getting started with mine. Hope it goes well for you.[/QUOTE]

Thanks. ESW has been great and is making it right. They have been a great company to work with, highly recommend. I learned a tremendous amount from this forum when I got mine. We love ours and I agree it can be a decent burner when used properly. My only concern is that I tend to not be able to shut it down as much as I'd like and still keep the heat up. Once a full load is going I leave the bottom knob 1-2 cogs open (1/16" crack), and the top slide 1/2 to 3/4 closed. This typically gets me 4 hours of "good" heat and another 2-3 of "so, so" heat. (dry wood <22%, well educated from this forum) I mostly burn 1 year ash and cherry. Hoping to get a little more heat from some 2 year red oak when it gets frigid. I did install a stove pipe damper this year and will experiment with that to try and get more heat out of the unit. Any suggestions are welcome.

brenndatomu

Minister of Fire

It will be good to go immediately.Should I wait a day to fire it up or is the weld good once finished? No experience with welding.

lexybird

Minister of Fire

I ran a inline butterfly flue damper 18" up from the furnace . I would recommend one to keep more heat in the unit where it belongs . Watch you give it ample time when you add a fresh load of wood before you Taper back the air and tilt your flue damper . It's a busy world these days and A lot of guys get in a rush and don't crack the door for 15 minutes to give it the good initial burn off time to get the heat up in the firebox and start the char process ... If you just add wood on coals and close it down it just cakes up and smolders till it takes off. Little things like this can make a big difference in how clean it burns. The dryer more seasoned the wood the less incoming air it requires to stay burning and the less air means a longer burn time which is what you want . If your giving it a lot of air on that above slide and the ash knob -your never going to get 8 hours of burn out of it

Last edited:

Thanks guys. Welder did a good job I think. New high temp paint. Ready to go. I do try and make sure its charred well before closing. Seems to catch from front to back though. Rarely get good flames in the back on start up. Would just love to get that 10-12 hr burn some get. How much do you shut your damper?

Thought I would show a couple pics of the fix. So far it's held great and looks good. I also added a couple cut fire bricks to shield the bottom door weld and corners. So far the stove has been twice as good as last year with the changes I've made this yr (dry wood and more efficient ducting). Thx for all the help.

Attachments

We have an englander as well. Our flue temps are normally 300 to 500. We try to maintain 400. ThTh temps on the front right above the door after a fire has been running for a while are usually about the same as flue temps. We haveover fired this aat least once. Warped the baffle plate and cooked the thermostat. We stillhave had no isues with the furnace other than when the power went out it over heated the new thermostat so now we just put the blower on a timer at night and all is well.

Same here. Our hot spot is to the left of the door about where the handle is. Keep flue around 450-500 with probe therm and face about 350-400. Had the pipes a bit hot twice and warped the baffle slightly, but don't think the unit quite got to over fire. Other than the crack we have loved ours. How hot did you get it?

I'm not quite sur. I know the magnetic thermometer fell off. Only thing I noticed once it cooled down was the baffle was warped. The other time the thermostat was taken out it only got up to about 600ish but with no air to it the thermostat was taken out

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 554

- Replies

- 21

- Views

- 2K

- Replies

- 16

- Views

- 1K

- Replies

- 8

- Views

- 1K