So I've been doing a ton of research, and am looking at building a boiler based on the Richard C Hill Wood gasifier boiler similar to the one @Hobartian has built: https://www.hearth.com/talk/threads...-based-on-the-design-by-richard-c-hill.68593/

I have a few questions after seeing his, and the original design, that I'm hoping someone on here can help me answer.

Any help or insight is greatly appreciated.

Thanks

Warren

I have a few questions after seeing his, and the original design, that I'm hoping someone on here can help me answer.

- What are the benefits or drawbacks to using a square burn and secondary chambers instead of cylindrical?

- How do I determine burn chamber size to fire tube to secondary chamber proportions?

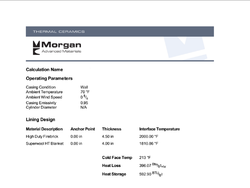

- In the original documentation from Richard, he mentions using Plicast 27 and 20 for liners, with some fire bricks, and then a vermiculite casing, is there any reason I can't build the chambers and fire tube out of hard fire bricks?

- Instead of vermiculite, I'd like to encase the whole unit in steel, one to match the hopper, and make a cleaner look, and also for durability, and the ability to rebuild the internals later if needed. I was thinking of building in a few pieces, 1 box for the 2 chambers and the fire tube, the hopper, the heat exchanger, and having them join together with some bolts and some stove gasket making it relatively easy to disassemble for cleaning and maintenance purposes, and then using a fire brick tube and chambers, surrounded by either insulating fire bricks, or refractory insulation matte. How would I determine how much matting I need to keep the outside of the rig at a safe temperature?

- I see the original design, and @Hobartian recommended using http://www.ebay.com/sch/i.html?_kw=GAST+REGENAIR+BLOWER+R1102 for the intake blower, what should I be looking for in ideal characteristics for the induced draft blower on the exhaust?

- If i go with my idea of a steel casing, do I need to give a separation between the casing, and the primary and secondary air inlets to prevent heat transfer to the outer shell?

Any help or insight is greatly appreciated.

Thanks

Warren

Last edited:

.

.