I've been toying with the idea of building some long (as in 4' wide x 100' long) roofs over my long stacks, to season and shed in-place, as opposed to the more typical 10' x 20' dual bay with single pitch roof sheds I see here. My reasoning is that, with processing and moving as much wood as I do, I can't bear the idea of stacking out in the open, and then handling that much wood again to pack it in a shed in the months or year prior to moving it up to the house and stacking it on the porch (three moves, post-splitting?).

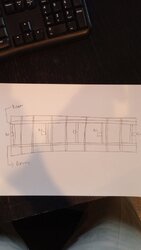

I have three stacks, each 4' wide x 100' long x 6' high. I'm thinking I can sink 6x6 x 10' PT posts every 8 feet down the centerline length of each stack, set a ridge between them, and build a nice little cedar-shake roof down the length of each stack. Attractive and functional. I'd leave 10 feet of space between stacks (i.e. stacks on 14' centers), so I continue to have a lot of room for maneuvering tractor and front-end loader with trailer between rows.

Seems absolutely brilliant, but then I wonder why this isn't the standard way of doing it? What's the down-side in this idea?

I have three stacks, each 4' wide x 100' long x 6' high. I'm thinking I can sink 6x6 x 10' PT posts every 8 feet down the centerline length of each stack, set a ridge between them, and build a nice little cedar-shake roof down the length of each stack. Attractive and functional. I'd leave 10 feet of space between stacks (i.e. stacks on 14' centers), so I continue to have a lot of room for maneuvering tractor and front-end loader with trailer between rows.

Seems absolutely brilliant, but then I wonder why this isn't the standard way of doing it? What's the down-side in this idea?