Hey guys,

I'm new to this site and hoping I can find some help here. I have a Millivolt fireplace with standing pilot and I'm having trouble with the valve assembly. The pilot lights fine and stays burning constantly but when I operate the wall switch although I hear the solenoid click the main flame does not start. I've measured the current from the wall switch and it is receiving 3 VDC.

So either the valve is no longer passing gas through to the main burners or possibly the solenoid isn't really opening?

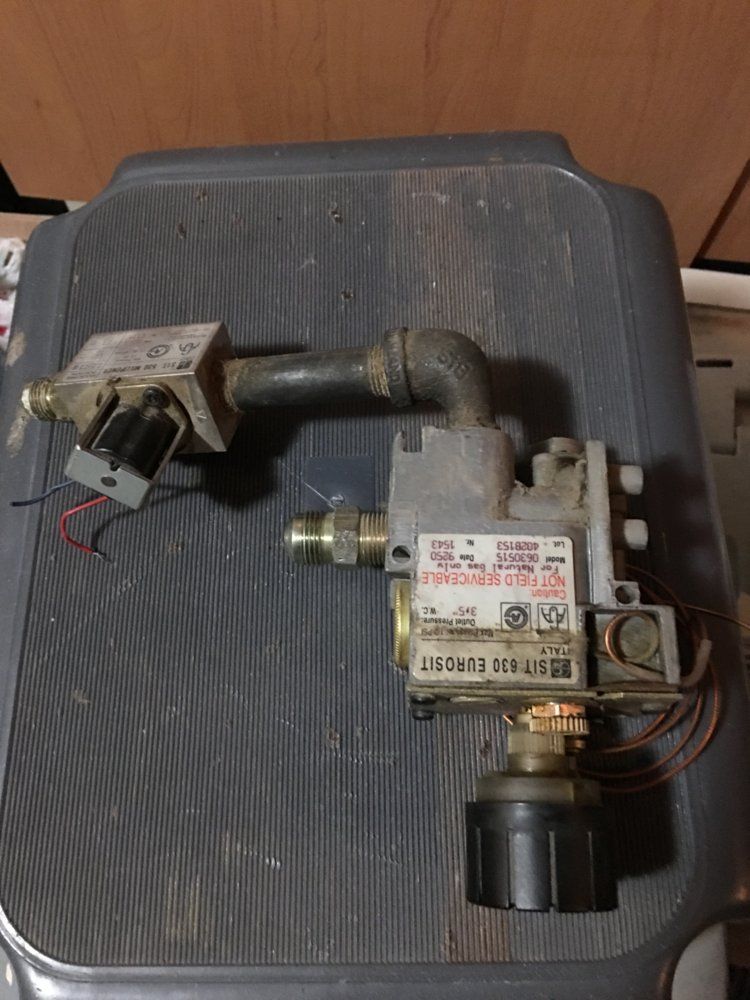

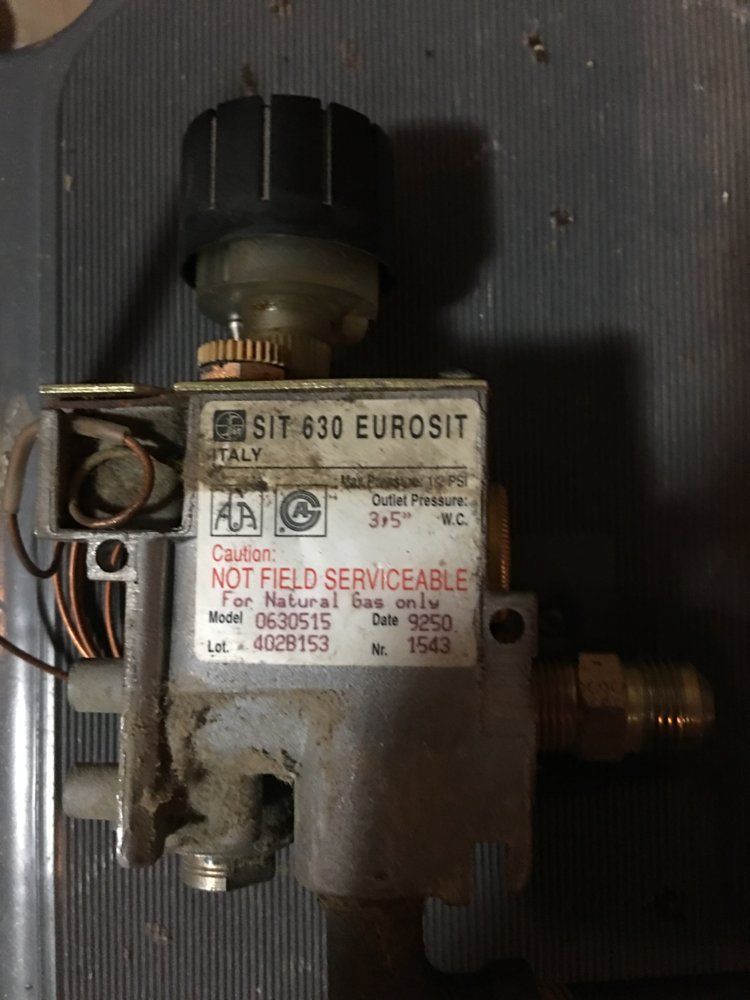

The valve is a SIT 630 Eurosit. The solenoid appears to be separate from the valve. I've included some pictures. I'm wondering about either troubleshooting this valve or trying to find a replacement for the complete valve assembly.

Any help would be greatly appreciated.

I'm new to this site and hoping I can find some help here. I have a Millivolt fireplace with standing pilot and I'm having trouble with the valve assembly. The pilot lights fine and stays burning constantly but when I operate the wall switch although I hear the solenoid click the main flame does not start. I've measured the current from the wall switch and it is receiving 3 VDC.

So either the valve is no longer passing gas through to the main burners or possibly the solenoid isn't really opening?

The valve is a SIT 630 Eurosit. The solenoid appears to be separate from the valve. I've included some pictures. I'm wondering about either troubleshooting this valve or trying to find a replacement for the complete valve assembly.

Any help would be greatly appreciated.