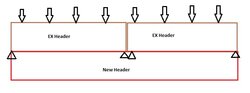

House remodeling. I need to enlarge (from 7 to 10-12 ft) and shift (about 5ft sideways) an existing header where one passes between rooms. On one side, the header has 2x8 ceiling joists nailed to its face; cathedral ceiling 2x12 rafters, on the other side, are nailed to the top of it. The existing header is a flitch beam, steel sandwiched between two 2x10s. I have computed (pretty conservatively) the load on the new header at about 900 pounds per linear foot (total) and about 575 plf of live load. There are several ways to proceed, and I can't decide among:

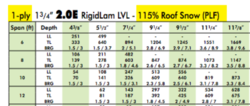

1. Sister a 2x10 piece of LVL (engineered wood) to the exposed face (the cathedral side) of the existing header. Unfortunately, the original carpentry was a little sloppy, and the existing header isn't directly on top of the girder which supports the floor which supports the wall with the header). Unfortunately, it's off to the side of the face where I'd add the LVL, so it'd be unacceptably off center after I did that.

2. Rip out the existing header and replace it with a 2-ply LVL beam (3.5" x 9.5"). This is "best" in the sense it's very strong (so can make the opening 12ft wide instead of 10ft). But a gigantic PITA: have to build temporary supporting walls on both sides of existing header, sawzall the thing out of there, etc. Oh, did I mention that almost every piece of Romex in the house runs right along the edge of this header ? At least I can do my own electrical work ...

3. Like #2, except after all the sheetrock is off, try to remove the flitch plate from the existing header, and the 1/2" plywood from the part that wasn't formerly over the opening, and then insert a new fitch plate of the proper length. Probably a non-starter too, especially if they used glue when they built the original flitch beam.

4. Put some sort of piece of structural steel under the existing header. I'm currently favoring this option. Not sure what to use - angle, square tube, channel ? Strength shouldn't be an issue. Deflection definitely is - there's no framing or door, but there is sheetrock; I've been told up to 1/2" might be ok. That means I need a section with a moment of inertia of about 10 in^4 (if I'm computing correctly).

Thoughts on what I should do ? Thanks !

1. Sister a 2x10 piece of LVL (engineered wood) to the exposed face (the cathedral side) of the existing header. Unfortunately, the original carpentry was a little sloppy, and the existing header isn't directly on top of the girder which supports the floor which supports the wall with the header). Unfortunately, it's off to the side of the face where I'd add the LVL, so it'd be unacceptably off center after I did that.

2. Rip out the existing header and replace it with a 2-ply LVL beam (3.5" x 9.5"). This is "best" in the sense it's very strong (so can make the opening 12ft wide instead of 10ft). But a gigantic PITA: have to build temporary supporting walls on both sides of existing header, sawzall the thing out of there, etc. Oh, did I mention that almost every piece of Romex in the house runs right along the edge of this header ? At least I can do my own electrical work ...

3. Like #2, except after all the sheetrock is off, try to remove the flitch plate from the existing header, and the 1/2" plywood from the part that wasn't formerly over the opening, and then insert a new fitch plate of the proper length. Probably a non-starter too, especially if they used glue when they built the original flitch beam.

4. Put some sort of piece of structural steel under the existing header. I'm currently favoring this option. Not sure what to use - angle, square tube, channel ? Strength shouldn't be an issue. Deflection definitely is - there's no framing or door, but there is sheetrock; I've been told up to 1/2" might be ok. That means I need a section with a moment of inertia of about 10 in^4 (if I'm computing correctly).

Thoughts on what I should do ? Thanks !

Last edited: