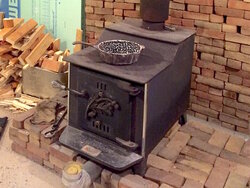

New to the site - great wealth of experience and knowledge here. I have an old Penn Stove Blue Flame c.1980 that I've been using for 17 years that was here in the house when we bought it.

The internal flame baffle plate broke off the back wall (where those horizontal marks are, which seems too low anyway) so currently all my heat is flying up the flue.

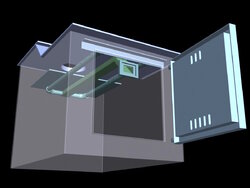

I've been pushing off the task of welding in a new plate, but with all the talk of efficiency I think I want to add a secondary air system along with it. My idea is to build a setup that includes the baffle and the air pipes and draws air through the top vent holes in the door.

Any thoughts on this design? This stove EATS wood and I either need to do something like this mod or buy a new EPA stove.

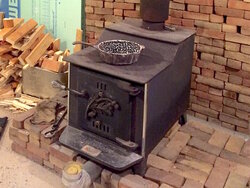

The internal flame baffle plate broke off the back wall (where those horizontal marks are, which seems too low anyway) so currently all my heat is flying up the flue.

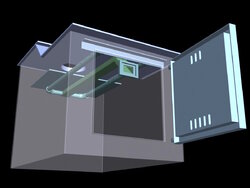

I've been pushing off the task of welding in a new plate, but with all the talk of efficiency I think I want to add a secondary air system along with it. My idea is to build a setup that includes the baffle and the air pipes and draws air through the top vent holes in the door.

Any thoughts on this design? This stove EATS wood and I either need to do something like this mod or buy a new EPA stove.

Last edited by a moderator: