I received my used propane tanks yesterday and would like to get started on putting in my ports as soon as possible so I can get started on the install when spring hits. I have two 250 gallon tanks that are going in horizontal in my crawl space. I'm needing advice on plumbing the 2 tanks to work with my system. I'm using a HX in the current duct work of the natural gas furnace, and I'll be running a sidearm for DHW.

I have this drawing that I made hoping this would be a good starting point.

View attachment 174886

The supply manifold would go in the top of the tanks and the return in the bottom. I drew them on the boiler manifold, but I wasn't sure where to plumb the HX and sidearm. either the boiler manifolds or build their own manifolds? Could anyone help me out with this plumbing? If any other information is needed let me know.

========================================================================================================

Before you go any further:

Please order at least 2 of Dan Holohans books from Amazon.

The first one is "Pumping Away" and the second one is Classic Hydronics".

With these tow books your going to prevent the mistakes you now have on paper

long before you start hacking and whacking.

Trust me the books are worth every penny and they will save you thousands of

dollars in mistakes-they did for me when I installed my Keystoker Coal Stoker boiler.

Unless your crawl space is insulated I would seriously consider changing the location of the tanks.

The ground temperature is going to be 52 degrees or lower in the crawl space and your propane tanks are

going to shed heat to the ground.

you will lose more heat to the ground than the tanks will give off to the floor, yes you will.

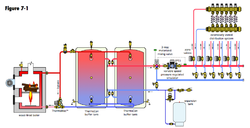

You need to revise your plumbing as well- the tanks need to be plumbed in series not series parallel this is only going to make

a mess for your plumbing and you will have no point of pressure change in that mess and your water is simply going

to sit there and not move.

Where is your Pump?? I hope it is on top of the boiler because you are going to be pushing a lot of air through the system

unless you change the tank plumbing to series plumbing.

if you install a steel expansion tank you will have a much easier time in doing plumbing and not require an air scoop

and the steel expansion tank will not fail like a bladder expansion tank will- We just changed the one on my father

boilers that has been bad for 2 years as my brother did not know what he is doing-typical.

Please Order the two books I mentioned as Dan helps the layperson and the plumber both understand hydronic heating.

I am just trying to save you thousands of dollars and headaches.