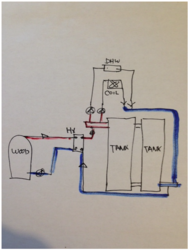

Used to do this for domestic hot water in 30 floor apartments with electric boilers....Parallel can work IF you can balance them (start with "reverse -return" piping) but series systems are a lot easier to monitor and stratify, especially with horizontal tanks.

I like the crawl space idea provided you insulate the walls and the tanks....

I like the crawl space idea provided you insulate the walls and the tanks....