Here are some pressure drop numbers from Viega, I imagine other brands would be similar.

I agree that 7.5 GPM is right at 4 feet per second velocity. Exceeding that and you start to get velocity noise and excessive wear in the fittings, especially those close turn ells.

At a 20° ∆T you could expect about 75,000 BTU delivered. If the building heats fine with the 130,000 gas boiler, call it 105,000 at 80% efficiency, you are not going to be able to move that much energy from the OWF. You may sneak up on it a bit by upsizing the pump, but will will have excessive velocity.

By far the most common error we see on this site is undersizing the pex from OWF to the loads. You are covering a portion of the load, on mild days you may be fine, so the rest of the wood is heating the great outdoors from where it came

Thats really strange that CB recommends and installs most of their boilers with 1 inch, but your correct, I was looking at generic flow data and it was saying you get about 10,000 btu per 1gpm. I honestly think if I could get 75k btu it would work OK if the temp was high enough in the baseboards. I would be happy at 75k delivered. I bet now its probably closer to 40k or less.

The air scoop is there, its just been mounted incorrectly- vertically so it isn't doing anything. I didn't set up up that way, but am going to change when I re-plumb the house boiler or upgrade it. I haven't yet because Im kicking around the idea of a 95% wall mount model and having it installed. Theres an auto bleeder on the outbound manifold.You have a circulator not a pump.

You have too much operating water pressure in the boiler.

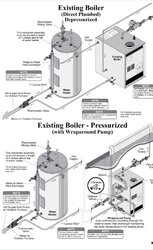

Your circulators need to be pulling water off the top of the boiler not pushing it into the sump of the boiler.

The point of no pressure change is where your bladder tank is located in your system.

Where is your air scoop?????

Ideally you want to pipe the boilers in series then to the heating load then from the return header back to the boiler or boilers

Can you install a domestic hot water coil in the fossil fuel boiler??

Are you able to bypass the wood boiler when the heating season ends??

You have to much plumbing and that is making a mess of things

A simple one pass circular domestic hot water coil would solve most of your issues.

By the looks of your system replacing it with a storage tank would solve all most all your heating issues and eliminate the HX mess completely

What do you mean by series? I don't want the water from outside mixing with water inside the gas boiler.

They(CB) run them from water heater to boiler exchanger, back to wood boiler.

.

I added the ten plate because the water heater is only 40 gallon and with 4 showers and laundry every day the 40 gallons goes quick. The 10 plate preheats it so its endless hot water, whereas the side arm keeps it hot once its in the tank, so the water heater never kicks on when its idle. That 10 plate is surprisingly powerful. With a flow rate of 6GPM, I am going to remove it though.

The large exchanger is 60gpm, so I see no restriction there.

So, the gas boiler thats here now has a long story behind it. The way it is installed is not by desire.

The short story is this.

I bought the house foreclosed as a new build that after ten years was never finished, the guy went bankrupt, it sat 7 years empty. All the Baseboard lines were frozen and broke in the basement. The guy had an identical laars teldyne mini furnace, same size and model except it was a thermal draft furnace. You would fall out of your chairs if you saw how it was installed and operating. It was horizontally vented with dryer vent... He also had a 95% efficient 90k btu lp forced air in the office attic, and another 90k lp forced air in the attic of the upstairs with an ac unit attached and a coal stove in the basement. He took the forced air/ac and coal stove when he left. It was pretty obvious he never got the radiant heat working right.

I saw the death trap draft furnace and I had only 3 days to get the house heated for appraisal. I had 3 estimates and then I had them replace it with an exact model, except it was induced draft. The contractors all agreed it would heat the house without any trouble and it does. It was obvious the old boiler plumbing was not correct at the boiler, but I didn't have time to rip it out and start over, the new mini was slid in, converted to lp,inspected for gas leaks, filled and fired the night before appraisal. Its always worked really well despite the wonky pump flow.

I really appreciate all of this help. It seems I most certainly came to the correct place. I have identified several problems and appreciate all the feedback.

According to the Taco manual, this puts me in the 0011 pump selection category.