In an open pressure system how far vertically up can water be pumped before it becomes an issue?

In my situation I need to pump vertical up about 10'(from the bioler to ceiling) to get over windows then back down to concrete level and enter underground pex.

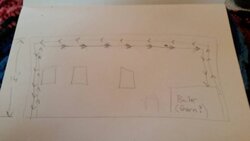

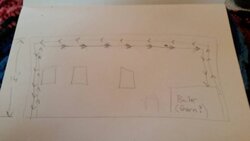

Attached is sketch of my situation.

Thanks

In my situation I need to pump vertical up about 10'(from the bioler to ceiling) to get over windows then back down to concrete level and enter underground pex.

Attached is sketch of my situation.

Thanks