Ive always wanted a wood burning stove. After researching a little (and reading the fisher story!) I knew I wanted a fisher stove. I sort've wanted a papa bear stove (and still do) but locally people were asking $700+, which is typical around here. People think everything is worth more for whatever reason. A grandpa was priced at $1000 just down the road from me.

Anyway, searched on craigslist and a lady had one price at $500 and said she just moved in and wanted it gone. Offered her $250 and she agreed, but it was 3hrs away. No worries, I needed something to look forward to. Rented a uhaul and went after it!

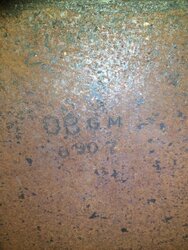

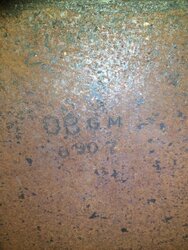

Its obviously not a 76, how can I tell anymore about the stove? It came with the screen for the front! Pretty happy about that, and a set of pokers and such.

Anyway, searched on craigslist and a lady had one price at $500 and said she just moved in and wanted it gone. Offered her $250 and she agreed, but it was 3hrs away. No worries, I needed something to look forward to. Rented a uhaul and went after it!

Its obviously not a 76, how can I tell anymore about the stove? It came with the screen for the front! Pretty happy about that, and a set of pokers and such.

Last edited: