Not exactly a wood boiler question, but I know someone here will know the answer. Plus I have an EKO 40 in the basement waiting to be installed to hopefully that counts?

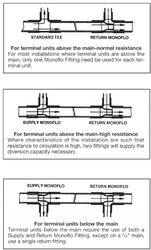

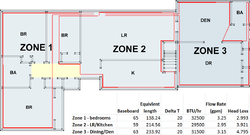

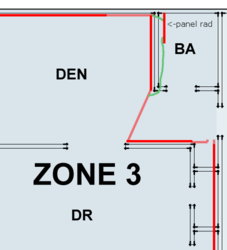

I am renovating a small 5x6 bathroom and bought a Runtal panel radiator to save on floor space. Right now the house is two zones, about equal length/size, all tube/fin baseboard. Burnham MPO-IQ84 oil boiler. I would really like to pipe it into the existing baseboard loop if possible. What's the best way to do that? Just plumb it in series? Or maybe put in two closely spaced T's and run it like a secondary loop?

I am renovating a small 5x6 bathroom and bought a Runtal panel radiator to save on floor space. Right now the house is two zones, about equal length/size, all tube/fin baseboard. Burnham MPO-IQ84 oil boiler. I would really like to pipe it into the existing baseboard loop if possible. What's the best way to do that? Just plumb it in series? Or maybe put in two closely spaced T's and run it like a secondary loop?