I've been lurking around for some time reading and thinking about building a log splitter myself. I like the idea of a heavy duty splitter but cant see myself paying the price that it would cost for me to buy one. so as it gets closer to burning season I decided that it was time to start some sort of construction. SO instead of doing that the old fashioned way with a napkin and pen I've gone to CAD and have drawn up really the heart of the splitter. Really i'm looking for some advice as to what some people think about the sturdiness of it. I have a feeling that the adjustable 4 way is too weak but opinions please.

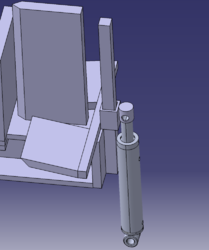

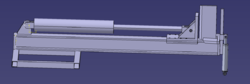

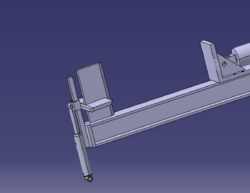

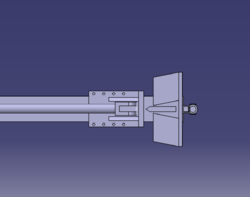

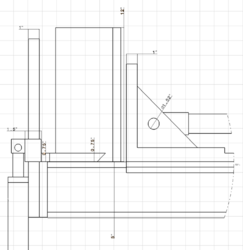

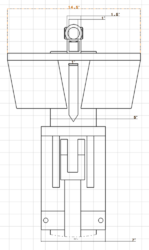

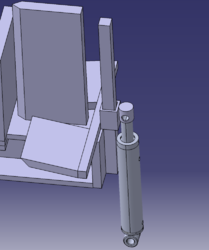

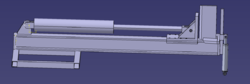

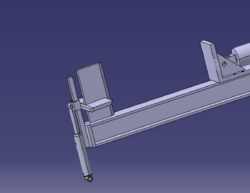

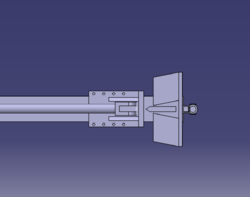

Picture 1 is a detail of how i planned the 4way. 2 and 3 are just views of the cylinders in retracted and extended, and 4 is an overhead of the wedge and pushplate

Picture 1 is a detail of how i planned the 4way. 2 and 3 are just views of the cylinders in retracted and extended, and 4 is an overhead of the wedge and pushplate