Bought the house in 2014 and the propane boiler had been replaced in August of 2013 IIRC. It's a 140k Crown Aruba 4(CI 83%) and the very first winter I noticed is was short cycling a lot. I immediately started researching about boilers as I'm not the type that hires anyone to do anything. I found that the boiler was massively oversized for my house, 2500 sq ft ranch. The house has about 60k btu of baseboards with three zones. I've been tracking the cycle time for the past two winters and found that on a day with a 17°F high/0° low that the boiler duty cycle was 37%. Besides being massively oversized there were quite a few things wrong with the setup. They had a 007 installed horizontally but the motor was on the top and the air scoop is after the circulator. The zone feed seems too small as well as it's 1" feeding three 3/4" zones. One point I feel lucky about though is that we moved in after the winter of the propane shortage but that has always weighed heavily on my mind. I decided that I was going to add a buffer tank and a pellet boiler so that I wasn't at the mercy of one type of fuel. This past spring/summer I picked up a used Harman Hydroflex 60 and a 120 gallon buffer tank. I've been reading a lot on the forums and have picked up a lot of useful information but there is always more to learn as this is not my field.

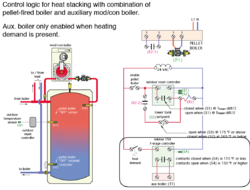

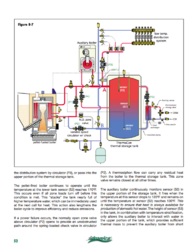

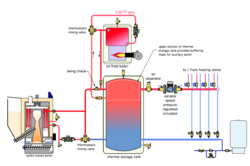

Basic plan layout is the propane boiler and pellet boiler run in parallel feeding the buffer tank. I'm going to leave the propane boiler controls intact and just use an aquastat in the buffer as a backup for when the pellet boiler runs out of pellets or I turn it off for cleaning. Just going to run 1 1/4" and a 007 for the propane boiler. I'm not 100% on the HF60s controls but from what I understand it will modulate in Auto mode to maintain a temp between the mix and max settings on the front. I'm going to run 1" and a Taco VT2218 in boiler protection mode so as to not cause creosote buildup. The circulator feeding the zones from the buffer is going to be an Alpha 15-55. I want to use a TACO ZVC-406 for control of the zone valves and house circulator. I have drawn up some rough schematic of the layout but I'm not sure anyone here wants to see my chicken scratch.

Just started with locating and thinking about how I'd like the layout to be. My basement has a garage door so I can bring in full pallets of pellets which is convenient.

Basic plan layout is the propane boiler and pellet boiler run in parallel feeding the buffer tank. I'm going to leave the propane boiler controls intact and just use an aquastat in the buffer as a backup for when the pellet boiler runs out of pellets or I turn it off for cleaning. Just going to run 1 1/4" and a 007 for the propane boiler. I'm not 100% on the HF60s controls but from what I understand it will modulate in Auto mode to maintain a temp between the mix and max settings on the front. I'm going to run 1" and a Taco VT2218 in boiler protection mode so as to not cause creosote buildup. The circulator feeding the zones from the buffer is going to be an Alpha 15-55. I want to use a TACO ZVC-406 for control of the zone valves and house circulator. I have drawn up some rough schematic of the layout but I'm not sure anyone here wants to see my chicken scratch.

Just started with locating and thinking about how I'd like the layout to be. My basement has a garage door so I can bring in full pallets of pellets which is convenient.

Last edited: