I've been looking around here for about a month and had a question I couldn't find the answer to in any forum. Is the only difference between fisher stoves with different doors the baffle plate? In my area, I can get a curved door fisher with baffle plate for about $1,000 and a 3 hr drive OR the older square door without baffle plate for $175 and 10 minute drive. If the baffle plate is the only difference then I may just get that welded in later. Just wanted a for sure answer on this since I couldn't find it. Thanks

Fisher difference, Curved door/ Square door

- Thread starter EastTN

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lake Girl

Moderator

Welcome to the forum ! Moved you to the Fisher stove section so it will catch coaly's eyes. Many of the wood burners are very knowledgeable but he appears to be the Fisher expert.

Appearance can be deceiving  .

.

The flat top doors were the first design and were used on the I (no shields) and II (1977 drawing revision with optional bolt on shields).

In 1979 the new Cathedral (arched top) Doors were introduced as an option. (Fireplace Series designated III, Bear Series designated VI) This is the only year both door styles were available.

In 1980 the flat top doors were discontinued and only Cathedral Doors were available until closing in 1988.

1980 also started a new style box that was UL Listed with bent corners, integrated shields bottom and rear and only double door stoves had the Smoke Shelf Baffle to reduce smoke. The baffle was only installed in the new style box without angle iron corners. Many fabricators continued to make the old style box with angle iron corners for use on a non-combustible hearth where the UL Listing wasn't necessary. (UL listing is now required in a new installation) They sold for $100 less and are more common. Either box style with double Cathedral Doors is a III. (Single door stoves would be a VI) Since the old style box was used in front of a fireplace using the existing larger fireplace flue, it makes sense not to offer a baffle since much more heat would be needed to be left up that type installation. The new style with shields and baffle would normally be used on a pad connected to an insulated chimney. Side outlet connected to a "through the wall" exterior chimney requires double wall inside since more heat is needed in the chimney flue.

You are only seeing what people are asking. There is no book value. A brass or nickel plated stove is more desirable, so may affect price. A later stove with UL tag should demand a higher price as well as glass doors. It takes time to find what you want at a good price, and prices are seasonal being much cheaper during summer months. Many people have no idea what they have and ask $1000 for their old stove realizing a new one is $3000.

I just saw a nice Goldilocks on Craigslist for $150 complete with balls under pedestal for use in a conventional built house, and tomorrow may see one for $1000 !

You should not have a baffle plate welded in place since changing chimney pipe configuration, flue size, as in a different installation or another owner will need it adjusted differently. It also looses the UL listing if it is a Listed appliance when permanently modified. Setting a baffle plate on bricks with angle iron attached to the plate at the sides can't go anywhere or move. I see no advantage of welding in place.

.

.The flat top doors were the first design and were used on the I (no shields) and II (1977 drawing revision with optional bolt on shields).

In 1979 the new Cathedral (arched top) Doors were introduced as an option. (Fireplace Series designated III, Bear Series designated VI) This is the only year both door styles were available.

In 1980 the flat top doors were discontinued and only Cathedral Doors were available until closing in 1988.

1980 also started a new style box that was UL Listed with bent corners, integrated shields bottom and rear and only double door stoves had the Smoke Shelf Baffle to reduce smoke. The baffle was only installed in the new style box without angle iron corners. Many fabricators continued to make the old style box with angle iron corners for use on a non-combustible hearth where the UL Listing wasn't necessary. (UL listing is now required in a new installation) They sold for $100 less and are more common. Either box style with double Cathedral Doors is a III. (Single door stoves would be a VI) Since the old style box was used in front of a fireplace using the existing larger fireplace flue, it makes sense not to offer a baffle since much more heat would be needed to be left up that type installation. The new style with shields and baffle would normally be used on a pad connected to an insulated chimney. Side outlet connected to a "through the wall" exterior chimney requires double wall inside since more heat is needed in the chimney flue.

You are only seeing what people are asking. There is no book value. A brass or nickel plated stove is more desirable, so may affect price. A later stove with UL tag should demand a higher price as well as glass doors. It takes time to find what you want at a good price, and prices are seasonal being much cheaper during summer months. Many people have no idea what they have and ask $1000 for their old stove realizing a new one is $3000.

I just saw a nice Goldilocks on Craigslist for $150 complete with balls under pedestal for use in a conventional built house, and tomorrow may see one for $1000 !

You should not have a baffle plate welded in place since changing chimney pipe configuration, flue size, as in a different installation or another owner will need it adjusted differently. It also looses the UL listing if it is a Listed appliance when permanently modified. Setting a baffle plate on bricks with angle iron attached to the plate at the sides can't go anywhere or move. I see no advantage of welding in place.

I'm looking for a mama bear freestanding stove to put in basement vented to a 25' interior chimney. Do you think a baffle plate would be beneficial or do you think it would be better not to have one? Also, near the end you mentionaed "setting a baffle plate on bricks" Is this a way to have a baffle in the stove without welding or an I missing your point?

Lets make sure we're on the same page. A Mama Bear doesn't have a factory baffle plate. It is from the Bear Series that has a single door that heats 1500 s.f. It has a 6 inch outlet and uses a 6 inch diameter chimney flue.

Your original question referring to a factory baffle would be found in a double door stove. Most have an 8 inch outlet for 8 inch chimney flue. There are some double door models that use 6 inch like Goldilocks or Teddy Bear with factory Smoke Shelf Baffles. Other models have baffles but not the Smoke Shelf design.

You need a stove with outlet size to match the chimney flue diameter.

Yes it would be beneficial to add a baffle to a Mama Bear providing the chimney is correct and baffle is adjusted for chimney flue diameter and height.

Correct, it doesn't need to be welded in place. It should remain adjustable in case it is connected to a different chimney.

This thread explains baffle design and how to set the plate on bricks on each side of stove. Not all Fisher Stoves are the same inside. Some will have a second course of brick changing baffle support.

https://www.hearth.com/talk/threads...d-fisher-more-heat-less-smoke-under-25.74710/

This is the Fisher Forum main page that has all the info you should need for Fisher specific info;

https://www.hearth.com/talk/forums/fisher-stove-information-parts-history-and-more.28/

(manuals at top in Sticky Section) Other threads in Sticky Section will identify stove models.

The search feature at top right will find other threads pertaining to baffles or other searchable keywords.

Your original question referring to a factory baffle would be found in a double door stove. Most have an 8 inch outlet for 8 inch chimney flue. There are some double door models that use 6 inch like Goldilocks or Teddy Bear with factory Smoke Shelf Baffles. Other models have baffles but not the Smoke Shelf design.

You need a stove with outlet size to match the chimney flue diameter.

Yes it would be beneficial to add a baffle to a Mama Bear providing the chimney is correct and baffle is adjusted for chimney flue diameter and height.

Correct, it doesn't need to be welded in place. It should remain adjustable in case it is connected to a different chimney.

This thread explains baffle design and how to set the plate on bricks on each side of stove. Not all Fisher Stoves are the same inside. Some will have a second course of brick changing baffle support.

https://www.hearth.com/talk/threads...d-fisher-more-heat-less-smoke-under-25.74710/

This is the Fisher Forum main page that has all the info you should need for Fisher specific info;

https://www.hearth.com/talk/forums/fisher-stove-information-parts-history-and-more.28/

(manuals at top in Sticky Section) Other threads in Sticky Section will identify stove models.

The search feature at top right will find other threads pertaining to baffles or other searchable keywords.

Thanks, that clears up a lot. Yes, the mama bear is the stove I'm looking for, have already dropped the 6" liner down my 13x13 terra cotta flue. I was under the impression that the curved door fisher was supposed to be the more improved fisher and had a baffle plate welded in to help with the effiency. I didn't know the double door stoves were the only ones with the baffle pre installed. So besides the door shape and way the legs are attached, is there any difference between the two? Just wondering if one is supposed to be more improved

Before 1979 all had angle iron corners and flat top door. They were tested by different Labs across the country since there was no common Testing Lab accepted in all states. So they were tested, but states didn't accept other areas testing specifications. Now UL is the only accepted testing specification nationwide. Most state and locals codes as well as insurance companies require UL Listed appliances which have a UL tag. They may be tested at a different Lab, but will have what UL Listing number they were tested to.

From 1974 to 1977 there was only one design of the single door stoves. All models were available with 3 vent options. Top, rear or side. There were left and right hinged doors for setting sideways on a hearth in front of closed off fireplace for a left or right side vented stove. This is what the original design was made for. In 1977 there were revised drawings sent to fabricators showing optional bolt on shields designated as a II. There are no tags on these older stoves and the only way to date them is knowing when changes were made to the draft cap, spring and handle size and shape. The flat top doors were dropped in 1980 for the newly designed model designated VI. So any stove built after 1979 will have the newer arched top door. The new UL listed design has rounded bent corners instead of angle iron corners and integrated shields. They are pictured in the VI manual. Here is what complicates Listed and non-listed models. Most fabricators continued to make the old style box with angle iron corners $100 cheaper than the UL Listed style. They could be used on non-combustible hearth where shields were not necessary. Since many codes now require all appliances Listed, these stoves "should" be much less since they can't legally be connected to a new installation. They are built just as well, they are not UL approved.

What make things confusing is the progression of the changes. You can always find the last of the old style shown below with UL tag that isn't normally found on a stove with the older flat top doors.

This was late '79 just before the design change for 1980. It had the first VI designated tag;

This was late '79 just before the design change for 1980. It had the first VI designated tag;

Or you may find an interim stove using up an old part like a left over flat top door on a newer style box stove. This is not the norm.

Or you may find an interim stove using up an old part like a left over flat top door on a newer style box stove. This is not the norm.

The new UL approved design for 1980 is shown in the first post of the Brochure thread;

https://www.hearth.com/talk/threads/fisher-brochures.100409/

From 1974 to 1977 there was only one design of the single door stoves. All models were available with 3 vent options. Top, rear or side. There were left and right hinged doors for setting sideways on a hearth in front of closed off fireplace for a left or right side vented stove. This is what the original design was made for. In 1977 there were revised drawings sent to fabricators showing optional bolt on shields designated as a II. There are no tags on these older stoves and the only way to date them is knowing when changes were made to the draft cap, spring and handle size and shape. The flat top doors were dropped in 1980 for the newly designed model designated VI. So any stove built after 1979 will have the newer arched top door. The new UL listed design has rounded bent corners instead of angle iron corners and integrated shields. They are pictured in the VI manual. Here is what complicates Listed and non-listed models. Most fabricators continued to make the old style box with angle iron corners $100 cheaper than the UL Listed style. They could be used on non-combustible hearth where shields were not necessary. Since many codes now require all appliances Listed, these stoves "should" be much less since they can't legally be connected to a new installation. They are built just as well, they are not UL approved.

What make things confusing is the progression of the changes. You can always find the last of the old style shown below with UL tag that isn't normally found on a stove with the older flat top doors.

This was late '79 just before the design change for 1980. It had the first VI designated tag;

This was late '79 just before the design change for 1980. It had the first VI designated tag; Or you may find an interim stove using up an old part like a left over flat top door on a newer style box stove. This is not the norm.

Or you may find an interim stove using up an old part like a left over flat top door on a newer style box stove. This is not the norm.The new UL approved design for 1980 is shown in the first post of the Brochure thread;

https://www.hearth.com/talk/threads/fisher-brochures.100409/

It's called an Insert, not a stove. Is this for the same installation you're looking for a Mama Bear for?

If so, you better give me the square footage you're heating so I can direct you to the correct Insert.

The Bear Series (single door) was originally designed to sit in front of the hearth sideways with a side vent. The hearth opening was closed off with a steel plate with a 6 inch hole for pipe. They were available left or right vent as well as left or right swing door to open away from wall. This prevents the stove from sticking out into the room.

1980 was the advent of the "Fisher Fireplace Insert" that uses convection heat from an outer air jacket and blowers that extract heat from the back half and still allows the front that sticks out to radiate or have exposed top for cooking. Only available with Cathedral doors, later models with glass, Brass and Glass or smaller sizes such as the Honey Bear or Cub Bear.

Fireplace Insert, no bear name given.

Fireplace Insert, no bear name given.

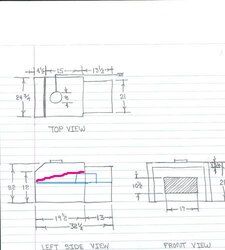

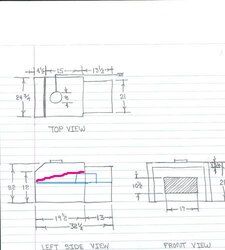

Dimensions and added baffle design;

Before you ask, they are connected to your liner with a "boot". Using that as a keyword on this site finds plenty of information in the Forum.

If so, you better give me the square footage you're heating so I can direct you to the correct Insert.

The Bear Series (single door) was originally designed to sit in front of the hearth sideways with a side vent. The hearth opening was closed off with a steel plate with a 6 inch hole for pipe. They were available left or right vent as well as left or right swing door to open away from wall. This prevents the stove from sticking out into the room.

1980 was the advent of the "Fisher Fireplace Insert" that uses convection heat from an outer air jacket and blowers that extract heat from the back half and still allows the front that sticks out to radiate or have exposed top for cooking. Only available with Cathedral doors, later models with glass, Brass and Glass or smaller sizes such as the Honey Bear or Cub Bear.

Fireplace Insert, no bear name given.

Fireplace Insert, no bear name given.Dimensions and added baffle design;

Before you ask, they are connected to your liner with a "boot". Using that as a keyword on this site finds plenty of information in the Forum.

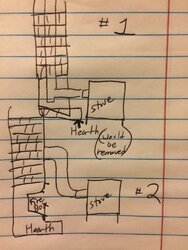

I was going to ask in the appropriate forum section, but if you don't mind I'll ask here or it can be moved. I didn't want to post everything at once because I didn't want to seem like I was wasting people's time with all my questions but I know people are here to help so I would like to thank you again. The whole story is this, with local prices, not including install, I looked at the P.E. Super $2,395 & Summit $2,795, Lopi Endeavor $2,358, Ironstrike Grandview 230 $1,864--300 $2,199, and Englander 30 $899. Most people online said they prefer the EPA stoves over the "smokedragons" but I live in East TN and electric bill isn't that high, just wanted a stove to burn on really cold nights. Given the local price of stoves mentioned and the amount I would burn seasoned wood in them, I feel that I'd rather just get a fisher stove. With that being said, when talking about installing a stove into existing fireplace, my plan is to do it one of two ways... either #1 Remove hearth and put stove where tee connector is sitting in picture and connect to liner vented thru bottom where fireplace is and up that way... Or #2 Put stove just a little further out and knock hole in brick (where flashlight is on wall) and put double wall pipe up from stove into brick wall connected to liner. Tried drawing a picture to explain what I meant as well

Attachments

If an insert fits the hearth why not use that? Heating capacity is greater than a Mama Bear's 1500. (double doors, takes longer wood and is UL Listed, easier to find in some areas, heats 1750 sf or more like 2000 in your area) - (Square footage was calculated for Seattle Wash. area with Fishers) It is not legal to reduce pipe or flue smaller than appliance outlet size, but the 8 inch Insert will physically work fine reduced if codes are not an issue. The insert was made to allow open door burning with screen in place with larger existing flues requiring much more heat. Your flue works very well with one. (and a damper is built into Insert) What is the floor material and would you have to extend hearth? Or is the opening too low to get the rear vent connector pipe under? Easier to extend hearth brick and cut legs down to fit rear vent under opening? The stove would still be plenty high enough from floor. That's what I would do. I notice steps next to stove area. What is the total square footage you'll be heating? Mama and Papa are the same height if total area is over 2000 sf. Is fire viewing desirable or a factor?

Double wall pipe is not necessary in diagram #2.

Double wall pipe is not necessary in diagram #2.

Wanting to go with freestanding stove because of radiant heat rising up because it's in a unfinished basement but is next to staircase that goes to main living area that's roughly 1,500 sq. ft. In front of hearth is concrete slab, that's why I've thought of removing the hearth and putting stove there just wasn't sure which option, 1 or 2, would be better for my freestanding stove install.

I'd go #1. But if the hearth opening is high enough for pipe from rear vent, I'd add another set of bricks in the front instead of removing them all.

You need to add the 1500 square feet upstairs to the downstairs area for the total heated area. If you have no insulation in basement, that area needs 1/3 more heat. (add upstairs area to downstairs area plus 1/3 of the square footage of downstairs area for total heated area).You need to consider your heating design temperature, insulation and windows to make the call between Mama or Papa Bear. (and how warm you like it)

Heated air will rise up your stairs but you also need vents through the floor at the opposite end of home for cool return air to drop back to be reheated. That gives you circulation across the upstairs for more even heating. A small duct fan in the vent blowing down will increase the upward flow. Code now requires floor vents to have fire dampers.

You need to add the 1500 square feet upstairs to the downstairs area for the total heated area. If you have no insulation in basement, that area needs 1/3 more heat. (add upstairs area to downstairs area plus 1/3 of the square footage of downstairs area for total heated area).You need to consider your heating design temperature, insulation and windows to make the call between Mama or Papa Bear. (and how warm you like it)

Heated air will rise up your stairs but you also need vents through the floor at the opposite end of home for cool return air to drop back to be reheated. That gives you circulation across the upstairs for more even heating. A small duct fan in the vent blowing down will increase the upward flow. Code now requires floor vents to have fire dampers.

If it's only a half inch, I would notch the fireplace with a masonry blade. I'm no expert on masonry fireplaces, but I would imagine there is a lintel or steel support across the opening. Don't know if they use "brick angle" like over doorways and windows but I would think it has to have something since it's not an arch with a keystone or similar. Masonry lintels have pre-stressed iron rods inside for strength, but they aren't close to the edge.

I would not have a problem cutting 1/2" off the legs compared to that much work.

You could probably have a sheet metal shop make you an offset piece or ovalized piece of pipe maybe? Perhaps try an adjustable el and twist the first section down and then back up to make it clear?? As long as you have a 6 inch, preferably insulated liner you should have no problem adding that little resistance.

I would not have a problem cutting 1/2" off the legs compared to that much work.

You could probably have a sheet metal shop make you an offset piece or ovalized piece of pipe maybe? Perhaps try an adjustable el and twist the first section down and then back up to make it clear?? As long as you have a 6 inch, preferably insulated liner you should have no problem adding that little resistance.

After reading your response and thinking about it, I believe I'll trim off a 1/4" at a time from the legs. That way the hearth and firebox, I believe is the term, will be even. Also, will build out the front and eventually cover the brick with some type of decorative rock. Thank you for all your help getting me this far

I'd measure and cut off what you need, save the pieces, they can be welded back later if needed. This is what I did with my Harman coal stove. It has a top flue and the 2" tall steel ring was about 3/4" too tall to fit under the stonework. I cut it off in one piece and put it away to be reattached later.

Similar threads

- Replies

- 1

- Views

- 532

- Replies

- 1

- Views

- 812

- Replies

- 5

- Views

- 721

- Replies

- 0

- Views

- 300