Is it better to push the how water from the boiler through the heat exchanger or pull it through?

Heat exchanger flow

- Thread starter Woodfarmer1

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

hondaracer2oo4

Feeling the Heat

Open system= push the water with the pump mounted at the boiler. Closed system = doesn't matter where the circulator is.

Top left is cold from house

Top right is cold to boiler

Bottom left is hot from house

Bottom right is hot from wood

Bottom pipe in background comes from the boiler hot, however it is pumping to the top right labelled cold to wood.

Essentially it's plumbed backwards?

Would this result in a loss of 20* from boiler to house?

Last edited:

maple1

Minister of Fire

maple1

Minister of Fire

Can't discern much without that. A good IR gun & flat black spray paint would help.

Also uncertain what you're saying about the background pipe. A zoomed out pic of everything there might help.

Deja vu here - I assume you didn't flush/clean the HX yet like you said you were going to do in your other thread? All the exposed copper will also lose heat.

Also uncertain what you're saying about the background pipe. A zoomed out pic of everything there might help.

Deja vu here - I assume you didn't flush/clean the HX yet like you said you were going to do in your other thread? All the exposed copper will also lose heat.

The background pipe is the one at the bottom on the two black hangers.

No I haven't got it flushed yet, the guy that plumbed this is coming any day....so I want to have all my info in case changes need to be made.

No I haven't got it flushed yet, the guy that plumbed this is coming any day....so I want to have all my info in case changes need to be made.

hondaracer2oo4

Feeling the Heat

As far as losing temp between boiler and house the answer is no, Btus dont just disappear because water is moving one way or another. BTUS are lost through an exchange somewhere. You said you are losing 20 from boiler to house but have no way to measure that? How do you know you are losing that. We do need all the numbers(temp at boiler, temp entering house, temp entering hx on both sides, temp leaving hx on both sides). If you are really losing 20 from boiler to house that means your underground lines have ground water touching them and you are sending all your heat into the ground. Yes if the pump is pumping that way it should not be, flip it over, you can do that right now without a problem.

I should have just asked this on the thread I started "extracting more btus" but I'm just more concerned right now with the direction of flow.

The temp on my garn is say 170* and in my basement about 145*. 70' of underground.

I have lines similar to thermopex, both supply and return in an insulated pipe, buried down 5'. I don't have a high water table so I can't see groundwater being a factor

The temp on my garn is say 170* and in my basement about 145*. 70' of underground.

I have lines similar to thermopex, both supply and return in an insulated pipe, buried down 5'. I don't have a high water table so I can't see groundwater being a factor

hondaracer2oo4

Feeling the Heat

Similar to thermopex? What is it exactly? A picture of the product would help. How are you measuring temps? If you losing temp between boiler and the houses and temp is accurate then your lines are losing it.

maple1

Minister of Fire

Mismatched flows across the HX could cause what you might think is a heat loss - but heat is not being lost, it is just not being transferred as good as it could be. Imagine the Garn side pumping at 100gpm, and the house side pumping at 1gpm - not much heat would make it to the house, most of it would just go round & round the Garn loop.

Without accurate temp measurements everywhere (and subsequent other data, like head loss & flow rates) - you just can't tell where heat is or isn't going.

Without accurate temp measurements everywhere (and subsequent other data, like head loss & flow rates) - you just can't tell where heat is or isn't going.

Bob Rohr

Minister of Fire

counter flow through the Hx, looks like you have that correct.

A simple digital thermometer from the hardware store with a sensor is adequate for temperature measurement. Wrap pipe insulation or a rag around the sensor for best accuracy.

Azel has a handy dual thermometer, battery powered and it reads out delta T. Amazon could have one to you tomorrow

A simple digital thermometer from the hardware store with a sensor is adequate for temperature measurement. Wrap pipe insulation or a rag around the sensor for best accuracy.

Azel has a handy dual thermometer, battery powered and it reads out delta T. Amazon could have one to you tomorrow

Attachments

So this is the crud plugging up the y-screen and the inside of the copper pipe on the Garn side.

It's a creamy colour, a lot like the crud when the F**king anode rod disintegrated.

I've pulled the HX off and currently the inside is filled with CLR.

My homeowner torch isn't hot enough to melt the existing solder, so i cut everthing off with the sawzall, help....waiting for a buddy with a better torch tomorrow, good thing its not supposed to drop below freezing until Monday.

Last edited:

Bob Rohr

Minister of Fire

that looks like a pretty tight mesh for a Y strainer? Although there should not be that much gunk inside.

What type of water was the system filled with? Could be crap that was put in the system at first fill?

Some of the treatment chemicals that they put in public water these days can create sludge at high temperatures.

If it keeps reoccurring have the water tested to see what is going on, scale or sludge effects the efficiency of all,the components in the system, as you have discovered

What type of water was the system filled with? Could be crap that was put in the system at first fill?

Some of the treatment chemicals that they put in public water these days can create sludge at high temperatures.

If it keeps reoccurring have the water tested to see what is going on, scale or sludge effects the efficiency of all,the components in the system, as you have discovered

TCaldwell

Minister of Fire

I was pretty sure that would be the issue, how long has it been in service to get that way. It looks like anode debris. Not sure if you have your water tested but as bob suggests, treatment chemicals, hard water precipitate and the city water chemicals under heat can be factors also. Last summer I drained and cleaned garn, removed a 5 gallon pale of anode debris, mind you that represented 2 sets of rods. Used precision chemicals products and guidance. I have y strainers on both supplies on the hx, at this point checking the strainers shows all is good. While your friend sweating pipe, you might think about isolation valves at the hx, it will make future checking painless.

salecker

Minister of Fire

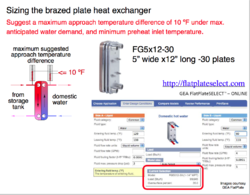

Looks like you need to change some of your fitting around for maximum efficancy.View attachment 192528

Top left is cold from house

Top right is cold to boiler

Bottom left is hot from house

Bottom right is hot from wood

Bottom pipe in background comes from the boiler hot, however it is pumping to the top right labelled cold to wood.

Essentially it's plumbed backwards?

Would this result in a loss of 20* from boiler to house?

I was told to hook mine up....

Top left hot to house

bottom left cold from house

Top right hot from boiler

bottom right cold to boiler.

The reason i was told was heat rises cold falls. So the way yours is plumbed, when you are removing the heat from your boiler water in your case you are then having to work against the laws of thermodynamics because you are forcing cold water against the way it wants to go.You are cooling your boiler water in the heat exchanger so it will want to fall naturally,but in your system you force it up

And when you add heat to your water from the house you are forcing it to go against the flow again,because it will want to rise when you add heat.

That may not account for the loss you are seeing.But it would help in efficancy and it will still work to some extent when you are in a power off situation.

salecker

Minister of Fire

Actually there isn't any counter flow.That is part of an efficiency problem,and mat be part of the difference temps.counter flow through the Hx, looks like you have that correct.

A simple digital thermometer from the hardware store with a sensor is adequate for temperature measurement. Wrap pipe insulation or a rag around the sensor for best accuracy.

Azel has a handy dual thermometer, battery powered and it reads out delta T. Amazon could have one to you tomorrow

It will work like plumbed,but not to the maximum efficiency that it could.

Bob Rohr

Minister of Fire

Bob Rohr

Minister of Fire

I had the water tested by precision chem and got the proper chemicals at the start of the season.

The hx is plumbed properly, the words on the board are just upside down.

I spent all after noon Saturday and Sunday un soldering and adding unions, it's almost finished, pics to follow.

The hx is plumbed properly, the words on the board are just upside down.

I spent all after noon Saturday and Sunday un soldering and adding unions, it's almost finished, pics to follow.

Bob Rohr

Minister of Fire

Just to be clear, here is a picture of proper HX installation.

Also a link to a free online sizing program. You could use it to confirm the capacity of your HX. The dimension and number of plates, even of it not the exact same brand.

Also a link to a free online sizing program. You could use it to confirm the capacity of your HX. The dimension and number of plates, even of it not the exact same brand.

Attachments

Here's my handywork, never professed to be a plumber.

I think I have it right now bob.

Top rear is hot water from boiler, bottom rear is return to boiler.

Top near is hot water to house and bottom near is return from the house.

Took a while to get all the air bled out of the system, but I'm already seeing closer temps on the supply and return.

House was 60* this morning with no heat nor sun for two days.

Scotty2

Member

Here is a link to an inexpensive touchless infrared thermometer...you can probably get something locally if you look around. I use mine all the time.I don't have any way to measure those at the moment.

https://www.loghomestore.com/1533-touchless-infrared-thermometer.php

Scotty

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 18

- Views

- 1K

- Replies

- 20

- Views

- 873

- Replies

- 9

- Views

- 2K