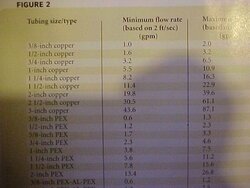

I was just wondering How much pipe diameter has to do with boiler performance when it is coming in from the outdoors. I know most folks have their pipes buried. I realize there are many different ways to insulate and bury, water proof and protect pipe coming in from an outdoor boiler, but what size is best? my system is 2 inch iron pipe well insulated above ground. Is 2 inch overkill. Is 3/4 too small. It must make a difference in the final performance for a system. The only reason mine is 2 inch is because it was free. The boiler manufacturers must have some recommendation as to what size is right for each system. Is there a simple rule of thumb??

Mike

Mike