HI, I am going to install my recently purchased Englander 12-FP stove over this next week. The first thing to do is to build a hearth and I would like your comments. So, my 2 questions are: did I calculate the R factor correctly and would you remove or leave the laminate flooring and laminate flooring sound deadening underlayment?

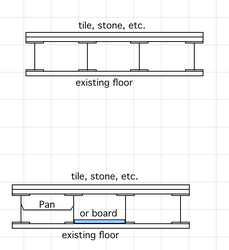

The floor is Columbia Colonial Clic laminate flooring and from what I can find I believe I would be safe to use an R value of .5. The laminate flooring sits on top of a laminate flooring sound deadening underlayment that sits on top of 2" of gyp-crete. I have purchased metal studs that I plan on "Liquid Nailing" to the gypcrete as I cannot screw the metal studs to the gyp-crete as there are radiant heat tubes in the gypcrete.

I am considering cutting the laminate flooring our in the shape of the hearth as I am not 100% sure of the R-rating of.5

I plan on putting concrete in between the metal studs and concrete has an R value of .92 per inch. I believe the metal studs are 1 5/8" thick so 1 1/2" of concrete would have a minimum R-value of .92 + (.92/2) = 1.38.

I plan on using 2 layers of 1/2" Wonderboard so that would be an R-value of .2 + .2 = .4.

I plan on the top surface of the hearth being 19" x 20" hearth stone (Cultured Stone) manufactered by Owens Corning and it has an R value of .355 per inch so this would be a total of .355.

Gyp-crete has a K value ranging from 4.75 Btu/(h · ft² · ºF) (.6840 W/[m · ºC]) to 5.15 Btu/(h·ft²·ºF) (.7416 W/[m·ºC]). This equates to a R-value range of 0.19 - .21 per inch. This equates to .19 x 2 to .21 x 2 = .39 - .42

Adding it all together I come up with .5 + 1.38 + .4 + .355 + .39 = 3.025. If I remove the laminate flooring I get 2.53.

The Englander manual says I need a minimum of R factor of no less than 2.

The floor is Columbia Colonial Clic laminate flooring and from what I can find I believe I would be safe to use an R value of .5. The laminate flooring sits on top of a laminate flooring sound deadening underlayment that sits on top of 2" of gyp-crete. I have purchased metal studs that I plan on "Liquid Nailing" to the gypcrete as I cannot screw the metal studs to the gyp-crete as there are radiant heat tubes in the gypcrete.

I am considering cutting the laminate flooring our in the shape of the hearth as I am not 100% sure of the R-rating of.5

I plan on putting concrete in between the metal studs and concrete has an R value of .92 per inch. I believe the metal studs are 1 5/8" thick so 1 1/2" of concrete would have a minimum R-value of .92 + (.92/2) = 1.38.

I plan on using 2 layers of 1/2" Wonderboard so that would be an R-value of .2 + .2 = .4.

I plan on the top surface of the hearth being 19" x 20" hearth stone (Cultured Stone) manufactered by Owens Corning and it has an R value of .355 per inch so this would be a total of .355.

Gyp-crete has a K value ranging from 4.75 Btu/(h · ft² · ºF) (.6840 W/[m · ºC]) to 5.15 Btu/(h·ft²·ºF) (.7416 W/[m·ºC]). This equates to a R-value range of 0.19 - .21 per inch. This equates to .19 x 2 to .21 x 2 = .39 - .42

Adding it all together I come up with .5 + 1.38 + .4 + .355 + .39 = 3.025. If I remove the laminate flooring I get 2.53.

The Englander manual says I need a minimum of R factor of no less than 2.