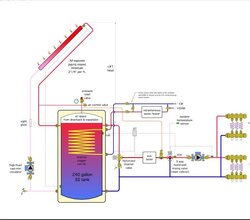

Here is a sweet little control and distribution logic a friend a Radiant Engineering shared, Siggy CADed it out.. It happens to be a solar drain back concept but could be wood fired, or backed up too.

The logic is this. Two delta t, aka differential or solar controls. Pick a brand they all do the same function. I like the new digital that store and share more info and have data screens. Easier to see, and log what is going on.

In this case one controller runs the solar input, simple enough.

The second delta t controller runs three way divertor valve.

A 3 way motorized mixing valve Taco, tekmar, Viesmann,a few others is run by an outdoor reset control function.

The "storage" sensor for the second delta t controller goes down stream of the 3 way motorized mixing valve. the "collector" sensor at the top of the storage. It POWERS the 3 way divertor valve at the storage tank. This allows that storage to be pulled down to the lowest possible temperatue. Based on outdoor reset, of course.

For solar you really, really, want to drag that tank temperature as low as possible every day to present the coolest possible temperature to the array the next morning. The cooler the return to the collector, the higher their efficiency and better their payback

The upper DHW preheat coil also adds to the draw down potential of the tank.

Same for any boiler really, the cooler the return the higher the efficiency. It's ALWAYS a delta t game.

In this drawing the backup boiler is a small water capacity electric boiler. As such it could pipe right through without much loss. If it were a larger as a fired, or wood boiler I'd primary secondary it into the loop.

The delta t control may have a function to "call on" the back up heater, most do.

I'd guess a contractor could buy the brains to this system for 5- 600 bucks. That Resol control may handle two of the three functions from one box.

Notice the way DHW is generated with a pre-heat coil in the solar tank, up high in the stratification, with an instantanous to back up. No standby losses, and the potential to "valve out" the instantanous in the summer. A LISTED anti scald valve at the DHW supplier is a MUST. ASSE 1017 point of distribution valve. Caleffi of course

Make sense?

hr