circulator pumps (circs) come in a lot of different sizes and styles. To size a circ you need to know how how many gallons per minute GPM you need to move and the system resistence (head).

Manufacturers will often give you this info for the boiler you chose. A rule of thumb is you need to move 1 gpm for every thousand BTUs.

I think nofo may be correct about wood boiler ratings being output not input. My EKO 40 shows a "power range" of 8-40, then states 85% efficiency. I'm not sure if the output is with or without the efficiency % figured?? Gas, oil,and LP boilers are typically rated as input BTU/hr.

Let say is does have an output of 40KW or 136,000 btu/ hr. In that case you need to flow, or move 13.6 GPM. that is the first number to use when sizing the circ.

The next is resistence to flow or "head" Every device, pipe, fitting, valve, etc in the piping circuit has resistence to flow. Again many boiler manufactures will give you a "head" number at different flow rates.

Wood boilers are typically fairly wide open vessels with little flow resistence.

Pipe also has resistence to flow at various flow rates. This can be determined by the size, length, and flow rate through the pipe.

B&G;has a free download System Sizer at their website that will give you this data.

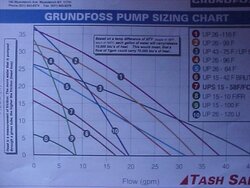

Once you know the head through all the components in the piping system, you can select a circ by looking at pump curve charts.

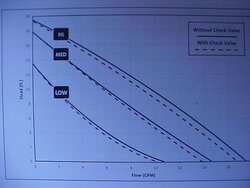

This one is for the Grundfos 15-58 3 speed I mentioned above, and a Grundfos one that covers a selection of circs.

If you use my "guesstimate' of 8 feet of head, and now 13.6 gpm follow the 8 feet of head line over the 13.6 gpm line. this circ is a bit small for the job. IF the system has 6 feet of head, then this circ would be perfect.

You want to shoot for the "knee" or middle 1/3 of the pump curve. Never size a circ at the very top or bottom of the curve.

Too large of a circ will use excessive energy, possibly add too much head energy. Excessive velocity in the pipe and components will cause noise, wear, and the circ may overheat and not last very long.

I sized the pressure drop "head" for your piping as you described, now you need to figure the head for the rest of your components to select the correct circ.

As luck would have it most circ manufacturers now offer 3 speed circs. This makes it much easier to match the circ to the job without shopping for the "exact" one.

In your case the 3 speed 26-99 might be a better choice. It will depend on the variable you have yet to determine. Or a wild guess based on experience

assuming around 6 ft of head.

assuming around 6 ft of head.