Hi guys,

This is my first post. I just bought a wood furnace used. I also bought the Class A metal chimney that he was selling. I assembled my chimney in a non-conventional way. I'll try my best to explain what I did, and some questions I have.

The return:

The return/motor has a 6" inlet. I bought a 6" starting collar and attached/screwed it onto the motor housing. It spins freely with no obstructions. I then used a 6" -> 8" reducer. Then I used 8" fiberglass insulated flex-pipe R4.2 into the return of the old furnace.

The outlet:

I have a 24" section of 8" pipe. I ran 8" fiberglass insulated flex pipe R4.2 through it, from top to bottom of the pipe (up to the stove). Then I connected that into a 8" starting collar in the ductwork of my old furnace. I know flex-pipe can be used in furnace set-ups, but what about a wood furnace?

The chimney/flue:

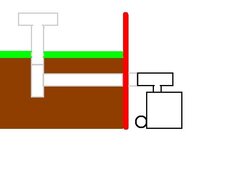

The flue is 6". I used a 8" section of 6" black-pipe. Then a T. I purposely used a T, so I can take off the cap and use my brush to clean it out from inside. There is a small section of 6" black-pipe, then a connector, then Class A chimney going into the brick foundation. This is where the chimney set-up become non-conventional. Instead of running it directly up to the peak of the house, I ran it horizontally 10 ft away from the house with a slight incline. Then I have a T with one inlet, one capped, and one opening with another 6" chimney section going up 3 ft. Then I have the piece ontop of the chimney that stops water from going into the system.

Fire bricks:

Some firebricks where damaged in the process of moving it into the house. I replaced them some ones that are similar. I tried to pack the bricks as tightly as possible. There is still a 1" gap in both of the sides of the chimney towards the middle. Should I cut a brick 1" to put in there? Or should I space out the bricks so there's small gaps between all the bricks? I've read without the bricks, there would be pre-mature wear in the firebox.

I know codes may/may not allow it. But the chimney setup seems that it should work. I tried to start my first fire this morning. I used paper and broken pallets (which I intend to use to fuel it for the rest of the heating season). I turned the blower on, opened the vent (above the glass door). I lit the paper and closed the door, but the pallet pieces would not burn. I lit the paper and kept the door open, and the pieces would still not burn. Smoke would come out of the air-vent (above the door), and the fire would not stay lit. After awhile, I went outside to see the chimney, and I did see a little smoke coming out. Is there a vent that I needed to open that I missed?

I don't understand why the fire wouldn't stay lit. I also don't know why the smoke doesn't go into the chimney and stays in the fire box. Should I have a bed of (char)coals or something? Attached is a diagram of my setup.

Thanks

-Tahleel

This is my first post. I just bought a wood furnace used. I also bought the Class A metal chimney that he was selling. I assembled my chimney in a non-conventional way. I'll try my best to explain what I did, and some questions I have.

The return:

The return/motor has a 6" inlet. I bought a 6" starting collar and attached/screwed it onto the motor housing. It spins freely with no obstructions. I then used a 6" -> 8" reducer. Then I used 8" fiberglass insulated flex-pipe R4.2 into the return of the old furnace.

The outlet:

I have a 24" section of 8" pipe. I ran 8" fiberglass insulated flex pipe R4.2 through it, from top to bottom of the pipe (up to the stove). Then I connected that into a 8" starting collar in the ductwork of my old furnace. I know flex-pipe can be used in furnace set-ups, but what about a wood furnace?

The chimney/flue:

The flue is 6". I used a 8" section of 6" black-pipe. Then a T. I purposely used a T, so I can take off the cap and use my brush to clean it out from inside. There is a small section of 6" black-pipe, then a connector, then Class A chimney going into the brick foundation. This is where the chimney set-up become non-conventional. Instead of running it directly up to the peak of the house, I ran it horizontally 10 ft away from the house with a slight incline. Then I have a T with one inlet, one capped, and one opening with another 6" chimney section going up 3 ft. Then I have the piece ontop of the chimney that stops water from going into the system.

Fire bricks:

Some firebricks where damaged in the process of moving it into the house. I replaced them some ones that are similar. I tried to pack the bricks as tightly as possible. There is still a 1" gap in both of the sides of the chimney towards the middle. Should I cut a brick 1" to put in there? Or should I space out the bricks so there's small gaps between all the bricks? I've read without the bricks, there would be pre-mature wear in the firebox.

I know codes may/may not allow it. But the chimney setup seems that it should work. I tried to start my first fire this morning. I used paper and broken pallets (which I intend to use to fuel it for the rest of the heating season). I turned the blower on, opened the vent (above the glass door). I lit the paper and closed the door, but the pallet pieces would not burn. I lit the paper and kept the door open, and the pieces would still not burn. Smoke would come out of the air-vent (above the door), and the fire would not stay lit. After awhile, I went outside to see the chimney, and I did see a little smoke coming out. Is there a vent that I needed to open that I missed?

I don't understand why the fire wouldn't stay lit. I also don't know why the smoke doesn't go into the chimney and stays in the fire box. Should I have a bed of (char)coals or something? Attached is a diagram of my setup.

Thanks

-Tahleel