Dan,

Yes, I agree that the instantaneous energy transfer for a shorted condition will "blow" by the fuse and adversely impact the 6 Amp Triac).

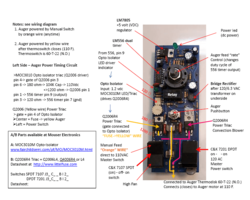

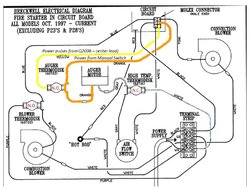

I will probably add a M.O.V. (metal oxide varistor) for general surge protection and 3 in-line fuses between (A) the Molex connector and the auger motor [orange wire] (vs just the auto auger feed yellow wire), (B) Molex connector and the thermodisc for convection blower [blue wire], and (C) the Molex plug and the combustion blower [pink wire] . In-line fuses are cheap and will better protect the controller board from several failures leading to electrical shorts.

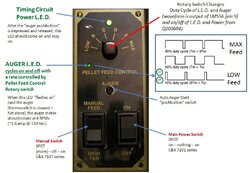

Strangely (at least in my opinion) the Manual Feed Switch

is not fuse protected so it basically cooked. Personally I thought the PC board trace would burn before the switch. Maybe the switch failure is just coincidental or it was on the edge of failure and this event pushed it over.

In any event, I am back in operating condition. That is, the pellet stove is cooking (better stated, it's heating).  For the Over Feeding Response:

For the Over Feeding Response:

I am a novice at best and by no means competent in Pellet Stove controllers. With that said.

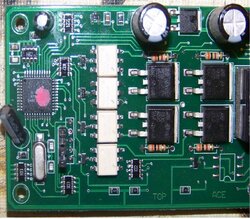

For the controller I worked on, here was my approach (this may not be appropriate for your controller):

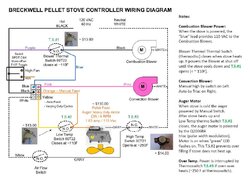

My controller is an old Analog Controller. And I don't have a thermostat connected.

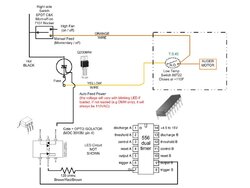

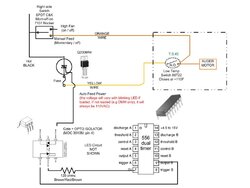

The yellow wire is for automatic periodic feed and is powered by the Q2006R4 triac.

The Q2006R4 triac is basically a switch that connects 110VAC to the auger (if the thermodisc is closed [stove hot]).

This Q2006R4 triac (switch) is controlled by the MOC 3010M opto-isolator.

WARNING: If improperly done this could result in board damage and / or electrocution.

For my work, I disconnected the controller board and temporarily wired it to a 110 VAC plug. This way, I could work on it on my workbench. With the power off and unplugged, I carefully connected a VOM (volt-ohm meter) lead to the "white power lead" and the other lead to the Yellow wire (and selected VOM to measure 110 VAC). Put the controller on a piece of wood or other insulating material.

In addition, connect the Auger motor to Yellow Lead and to White Lead. NOTE: If there is no load (if the motor is not connected), the Triac's output (yellow wire) will alway indicate 110 VAC and you will not be able to evaluate the Triac's switching function. With the motor connected it should cycle on and off when the Auger LED cycles on and off.

If the AUGER LED is cycling on too frequently it's probably due to the Resistor & Capacitor components (or possibly the diode required for a less than 50% duty cycle) connected to the LM556 timer. There are many tutorials on 555 /556 timers. The LM556 timer is just two 555 timers in the same 14 pin package.

I believe the adjustable resistor pot allows for adjustment of the auger cycle period time. If all is working, then adjusting this pot may be the correct and easy solution. I will confirm when I install the new switch next week.

Ref:

http://www.kpsec.freeuk.com/555timer.htm (better, covers 555 and

LM556)

Ref:

http://www.uoguelph.ca/~antoon/gadgets/555/555.html

Plug in via a power strip and use the power switch on/off to power control board.

1. Power On

observation: Neither LED should be on.

2. Depress auger pushbutton.

observation: Timing Circuit Power LED at TOP Center should come on and stay on.

after a 1 minute of so, the Auger LED should cycle on and off. The time on and off is controlled by the

pellet feed control (which changes the RC components connected to the 556 timer).

3. Does the auger motor come on

only when the Auger LED is on? So the Auger motor should rotate only when the Auger LED is on.

4. Does changing the Feed Rate Switch change how long the Auger LED is on?

5. Do you have the original Auger motor installed. Is it possible that you have the 4 RPM motor instead of the 1 RPM motor. My unit uses the 4 RPM heavy duty motor. My understanding is some Breckwell Pellet Stoves use the 1 RPM motor.

Just my thoughts. I am sure others will chime in. I am glad for this forum, it provides some great information thanks to some helpful folks.

Good Luck.

N. Man