I have read of many folks having a problem with the coal buildup from 24/7 burning. I have been adjusting to my T5, after last season burning a Morso, which has a cast iron grate built into the stove bottom. By contrast, the T5 has a firebrick floor with a small "ash chute" that I don't use because the ash drawer fits pretty badly and the concept of the ash chute is pretty weak to begin with. How do you convince all the ash to make its way to an opening smaller than 2x2" at the front middle of the stove ?

So I have similarly had the issue of a big buildup of coals and the issue of separating ash from coals when making space for wood again. So here are a few of the rules I have learned regarding how my stove works:

1) When setting the stove up for an extended burn (which is what most of us non retired people do..), we do the usual process: break up any big coals, spread the coals around to "level the field", remove any obvious ash deposit on top and at the front from the previous burn. Pile on the new splits, open the primary air all the way to char the new load and then reduce air to the "extended burn" mark and leave.

2) With the primary air at the "extended burn" point, I find that the vast majority of air entering the stove comes through the secondary combustion system, thus being directed top down onto the wood below and burning off any smoke that may come off the wood. It is the fact that air impingement is primarily from above that I believe is the cause of the large coal bed. It doesn't take long to form a layer of ash on top of the coals, which blocks access of the air to the remaining fuel, thus slowing the proces down and preserving the coals for a long time. Many of the coals are buried to the point that they die out and sit in charcoal format, just like many have said.

I think this situation is exacerbated by too high a draft, since the stove has stops built in to force a certain level of draft, even with all of the draft levers fully closed under "minimum" chimney conditions (low draft). The result is that in practice in northern latitudes with low temperatures, steep roofs and tall chimneys we need to operate our stoves at "minimum air" almost all of the time, that is if we do not need supplemental dampers to reduce chimney draft to a sane level. Under these conditions, minimal primary air is supplied, with the bias strongly toward secondary air only, over which we have no (legal) control.

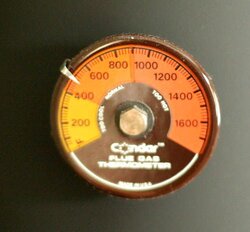

So by evaluating this picture, the right way to address the situation would be to balance the airflows of primary and secondary air, but none of us has a stove equipped to do this, since at the start of the burn one needs a lot of secondary air to burn off smoke, whereas at the latter (60%) of the burn one needs more primary air, directed under the fire to enable efficient burning of the coal bed. This is no secret, just look at any stove designed to burn coal and you will find the air directed below the fuel, as well as the grate to allow the small ash particles to fall through so as not to impede the flow of air.

So, at the risk of being long winded, here is how I have dealt with the situation. First of all, since ash tends to be fine, it also tends to end up at the bottom of the heap in the stove. After making a mess trying to rake live coals to the side to get to the ash, I tried a different way. I take my long handled ash shovel and simply shove it in the stove, trying to keep it directly on top of the firebrick. I then lift it up (pushing live coals to the side as it come up) and if required, I may give it a slight shake to make remaining live coals fall off. Out it comes and dump it in the ash bucket. Shove it in another time, this time just push it further back under the coals, lift it up again with the same result. I find that I get out almost all of the ash and carry out only a few small live coals. Repeat this procedure from one side of the stove to the other, working the front, middle and back (the T5 has a major depth dimension) then spread out the remaining coals (which are now exposed to air and glowing brightly). Load up the new spilts, char them and reduce the air as usual.

If I am home (mornings and evenings) after getting out the ash and loading a new load of splits, I open my ash chute. This lets in air below the base of the coal bed. I am generally able to reduce the primary air to the fully closed position, but now the air will be entering below the coals, rather than over the top. There is still plenty of secondary air, so no problem with smoke from the fresh load. Visually, the fire looks different, since the coal bed is glowing bright red, whereas with the ash chute closed it is dull. Under these conditions the coal bed is burnt down progressively at a faster rate than it builds up from the new wood which is added. If I go to bed or leave, I close the ash chute and burn with the primary air in its "regular" position and of course I will over time get the same buildup as before. That said, I no longer have any problems with making space in the stove to fit wood, nor do I have to shovel out charcoal or live coals.

I know all readers here do not have the same type of stove, so one has to figure out what could work in your situation. Perhaps an additional small "window" is added to the ash door to provide air under the fire (much safer than cracking the ash door).

Keith

So I have similarly had the issue of a big buildup of coals and the issue of separating ash from coals when making space for wood again. So here are a few of the rules I have learned regarding how my stove works:

1) When setting the stove up for an extended burn (which is what most of us non retired people do..), we do the usual process: break up any big coals, spread the coals around to "level the field", remove any obvious ash deposit on top and at the front from the previous burn. Pile on the new splits, open the primary air all the way to char the new load and then reduce air to the "extended burn" mark and leave.

2) With the primary air at the "extended burn" point, I find that the vast majority of air entering the stove comes through the secondary combustion system, thus being directed top down onto the wood below and burning off any smoke that may come off the wood. It is the fact that air impingement is primarily from above that I believe is the cause of the large coal bed. It doesn't take long to form a layer of ash on top of the coals, which blocks access of the air to the remaining fuel, thus slowing the proces down and preserving the coals for a long time. Many of the coals are buried to the point that they die out and sit in charcoal format, just like many have said.

I think this situation is exacerbated by too high a draft, since the stove has stops built in to force a certain level of draft, even with all of the draft levers fully closed under "minimum" chimney conditions (low draft). The result is that in practice in northern latitudes with low temperatures, steep roofs and tall chimneys we need to operate our stoves at "minimum air" almost all of the time, that is if we do not need supplemental dampers to reduce chimney draft to a sane level. Under these conditions, minimal primary air is supplied, with the bias strongly toward secondary air only, over which we have no (legal) control.

So by evaluating this picture, the right way to address the situation would be to balance the airflows of primary and secondary air, but none of us has a stove equipped to do this, since at the start of the burn one needs a lot of secondary air to burn off smoke, whereas at the latter (60%) of the burn one needs more primary air, directed under the fire to enable efficient burning of the coal bed. This is no secret, just look at any stove designed to burn coal and you will find the air directed below the fuel, as well as the grate to allow the small ash particles to fall through so as not to impede the flow of air.

So, at the risk of being long winded, here is how I have dealt with the situation. First of all, since ash tends to be fine, it also tends to end up at the bottom of the heap in the stove. After making a mess trying to rake live coals to the side to get to the ash, I tried a different way. I take my long handled ash shovel and simply shove it in the stove, trying to keep it directly on top of the firebrick. I then lift it up (pushing live coals to the side as it come up) and if required, I may give it a slight shake to make remaining live coals fall off. Out it comes and dump it in the ash bucket. Shove it in another time, this time just push it further back under the coals, lift it up again with the same result. I find that I get out almost all of the ash and carry out only a few small live coals. Repeat this procedure from one side of the stove to the other, working the front, middle and back (the T5 has a major depth dimension) then spread out the remaining coals (which are now exposed to air and glowing brightly). Load up the new spilts, char them and reduce the air as usual.

If I am home (mornings and evenings) after getting out the ash and loading a new load of splits, I open my ash chute. This lets in air below the base of the coal bed. I am generally able to reduce the primary air to the fully closed position, but now the air will be entering below the coals, rather than over the top. There is still plenty of secondary air, so no problem with smoke from the fresh load. Visually, the fire looks different, since the coal bed is glowing bright red, whereas with the ash chute closed it is dull. Under these conditions the coal bed is burnt down progressively at a faster rate than it builds up from the new wood which is added. If I go to bed or leave, I close the ash chute and burn with the primary air in its "regular" position and of course I will over time get the same buildup as before. That said, I no longer have any problems with making space in the stove to fit wood, nor do I have to shovel out charcoal or live coals.

I know all readers here do not have the same type of stove, so one has to figure out what could work in your situation. Perhaps an additional small "window" is added to the ash door to provide air under the fire (much safer than cracking the ash door).

Keith

I'm really interested by what you wrote about the amount of airflow going into the stove... it really explains the quick hot fires I get in the Alderlea. Good luck with your experiments in adjusting it so it works better for you!

I'm really interested by what you wrote about the amount of airflow going into the stove... it really explains the quick hot fires I get in the Alderlea. Good luck with your experiments in adjusting it so it works better for you!