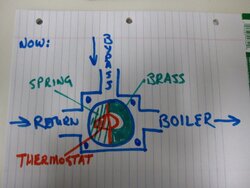

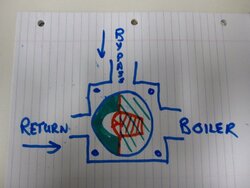

My Danfoss valve is making a noise when it opens and closes (keeping return temp to the boiler at 140*) that sounds like the song of the killer whale. Since the thermostatic valve in the Danfoss is always self adjusting for the temp, it is nearly constant once the boiler reaches 150* or above.

It isn't really a problem because the boiler is in the garage, but I haven't read on here that others have the same problem. It seems to be working OK, but I wonder if it is recirculating too much water to the boiler as well based on the temp difference between the boiler output and the loop temp. I have a ball valve in series with the bypass - should I try throttling back the amount of hot supply water which can be circulated through the Danfoss back to the boiler? This would increase my loop temp but might drop my return temp below 140*

Any thoughts?

It isn't really a problem because the boiler is in the garage, but I haven't read on here that others have the same problem. It seems to be working OK, but I wonder if it is recirculating too much water to the boiler as well based on the temp difference between the boiler output and the loop temp. I have a ball valve in series with the bypass - should I try throttling back the amount of hot supply water which can be circulated through the Danfoss back to the boiler? This would increase my loop temp but might drop my return temp below 140*

Any thoughts?