pen wrote:

>While I love the added heat gained from my wood, what I am not happy with

>is my flue gases. I now have smoke

I never did before except for

>about 10 minutes after a reload. From then on out, it would be nothing

>but heat waves. Now, I am getting 30mins on an average load to 60-75

>minutes on an overnight load of white smoke from the chimney. All the

>while the stove is producing killer heat and the chimney is about 350

>degrees (normal).

...and...

>I have discussed the smoking issue with the metal shop buddy who built

>this for me, and he believes even with the added smoking that I am going

>to find less 2nd degree creosote in the chimney since I am no longer

>needing to use my stove damper and the velocity of my flue gasses will

>have increased.

>

>Even if he is correct, the smoking issue bothers me from a smell

>standpoint (I like my neighbors) and an environmental standpoint (no tree

>hugger but I don’t like making a bigger impact than necessary).

>

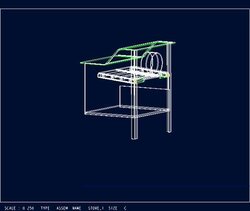

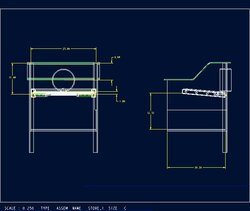

>My thought is that a simple secondary, while it may not be perfect, may

>add enough extra air in the back of this baffle to help better burn this

>smoke I am finding.

--

You've likely read this here before, but most people say white smoke that dissipates to the surrounding air quickly is likely (mainly) steam from the moisture in the wood. If it's dark and lingers (and has any odor to speak of), that's 'real' smoke.

Again, I'm far from expert, but I'm inclined to think that yes, the secondary _should_ help burn off the 'added' smoke.

Also, I might continue to use the flue damper judiciously. You don't really want a rapid velocity out of the stove proper... but rather a semi controlled 'reside time' within the stove to help mix volatiles, heat and air for complete combustion... before the exhaust enters the flue.

Peter B.

-----

I never did before except for

I never did before except for  Just me being over paranoid! However, the idea of including a secondary is still interesting and has created great conversation.

Just me being over paranoid! However, the idea of including a secondary is still interesting and has created great conversation.