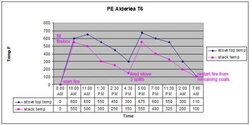

My Buddy's big monster stove was loaded up this morning and after it heated up to aprox. 500 ° he watched the Stove temp increases to 800 ° in the fire Box and flue temp lowers to 300 °??

He is going what the hell?

Anybody have this sort of reaction? He was burning well seasoned red oak for maximum btu output during this cold snap.

Also he said that he went out side and it looked like white smoke was billowing down from the chimney but he didn't smell smoke! is this moisture from the wood and the cold temps?

Anybody experience anything like this?

Thank you,Hiram

He is going what the hell?

Anybody have this sort of reaction? He was burning well seasoned red oak for maximum btu output during this cold snap.

Also he said that he went out side and it looked like white smoke was billowing down from the chimney but he didn't smell smoke! is this moisture from the wood and the cold temps?

Anybody experience anything like this?

Thank you,Hiram