New member to site. A lot of great info & a lot of smart ideas on site. Purchased Biomax 60 approx 6 mths ago w/intent to use storage for this winter. Now, just want to get hooked up w/no storage for this winter with plans to get storage after the winter. Have had quotes to install boiler but too extreme for pocket book. My background on this project is over my head & hope someone can help.

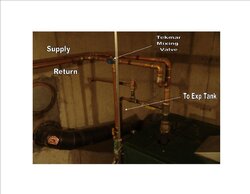

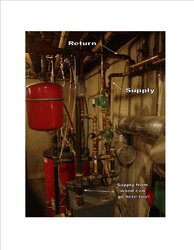

Background on where @ with project. Boiler in barn approx 100 ft from house. Underground tubing, chimney installed. Just purchased a lot of the tubing to begin the installation. Biomax doesn't have install manuals. Have the EKO manual but w/my background, need all the pictures can get. Does anyone have basic pictures / diagrames indicating where each component goes, how they are hooked up, etc.

When talk to folks, they make it sound simple (and it probably is). Pictures say a lot to my knowledge base. Any help would be appreciated!

Thanks in advance,

Steve

Background on where @ with project. Boiler in barn approx 100 ft from house. Underground tubing, chimney installed. Just purchased a lot of the tubing to begin the installation. Biomax doesn't have install manuals. Have the EKO manual but w/my background, need all the pictures can get. Does anyone have basic pictures / diagrames indicating where each component goes, how they are hooked up, etc.

When talk to folks, they make it sound simple (and it probably is). Pictures say a lot to my knowledge base. Any help would be appreciated!

Thanks in advance,

Steve