I learned something this morning which I have not seen in any post and which, as the data shows, results in an area of automatic variable flow circulator operation in conjunction with the Termovar return temp protection valve. This may be especially interesting for those who operate their systems with a system return to the boiler below about 155F. It likely will not be important for those who operate their systems with return temps above 155F.

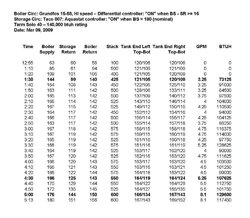

I changed my system over from a plate hx system to direct system operation. Reasons would be another discussion. I let the system cool down to depressurize for draining the boiler, which had antifreeze, and re-filling with water. Tank is horizontal 1000 gal LP. Piping is 1" steel between the boiler and tank. For this test the boiler was feeding only the storage, no other heat draw. I installed a flowmeter on the line to determine gpm.

The first interesting thing is the effect of the Termovar on boiler output to system vs feedback to boiler to maintain return temp. The data clearly shows that below about 150-155F system return to boiler, the Termovar is diverting substantial boiler output in the feedback loop back to the boiler, and as system return rises above this, the Termovar is diverting little if any boiler output in the feedback loop to the boiler. Initial boiler output to system was only 3 gpm at 96F system return to boiler, and boiler output to system maxed out at 8 gpm as system return to boiler reached about 155F.

The second interesting thing, although I did not record this for each data point, is actual Tarm output to system as related to stack probe temp. The burns during this data collection ranged between 400-500F stack temp (near the end, not included in data points, stack temps rose to 600F before coming back down). Stack temps closer to 500 produced the higher btuh outputs, and stack temps closer to 400 produced the lower btuh outputs. The Tarm is rated at 140,000 btuh, and the data shows that this can be reached only with stack temps above 500F.

A third interesting thing is effect of change in speed of the Grundfos UPS 15-58 on gpm's. My install is a bit unusual as I have the 15-58 on the boiler return, as normal, and I also have a Taco 007 on the tank return to the boiler, two circs operating to supplement each other. With the 007 shut down, but flow through the 007, 15-58 output was: Lo - 3.3 gpm, Med - 4.75 gpm, Hi - 5.50 gpm. With the 007 turned on, output was: Lo - 7.0 gpm, Med - 7.6 gpm, Hi - 8.0 gpm. All data shown below was with both circs on and the 15-58 on Hi.

A fourth interesting thing is that at gpm's below about 7, very little mixing was occurring in the horizontal tank and a high degree of stratification was occurring throughout the tank. As gpm's rose above 7, it was evident that mixing was increasing. I measured tank temp at both ends, top and bottom. For others with horizontal tanks, it may be important to keep the flow gpm's below 7 to achieve maximum stratification benefits. I have a diptube near the bottom of the tank for return to system, and supply to tank is about 1 foot from the diptube with a horizontal injection into the tank along the top and away from the diptube.

The last interesting thing is that during this entire test, the boiler did not idle at all. I continued the test past the data shown. My last data point collected is the final entry below. The absence of any idling maximizes boiler performance.

I fired the Tarm and let it come up to about 160F temp before turning on the circs.

Initial return from tank: 96F Boiler output: 160

gpm to tank: 3.0 Boiler return temp: 130 Output: 96,000 btuh

Return from tank: 130F Boiler output: 164

gpm tank: 6.25 Boiler return temp: 140 Output: 106,250 btuh

Return from tank: 134F Boiler output: 165

gpm tank: 6.75 Boiler return temp: 145 Output: 104,625 btuh

Return from tank: 137F Boiler output: 167

gpm tank: 7.50 Boiler return temp: 147 Output: 112,500 btuh

Return from tank: 142F Boiler output: 168

gpm tank: 7.75 Boiler return temp: 150 Output: 100,750 btuh

Return from tank: 148F Boiler output: 172

gpm tank: 8.00 Boiler return temp: 152 Output: 96,000 btuh

Return from tank: 153F Boiler output: 176

gpm tank: 8.00 Boiler return temp: 157 Output: 92,000 btuh

Return from tank: 156F Boiler output: 183

gpm tank: 8.00 Boiler return temp: 160 Output: 108,000 btuh

Return from tank: 159F Boiler output: 181

gpm tank: 8.00 Boiler return temp: 160 Output: 88,000 btuh

Return from tank: 162F Boiler output: 183

gpm tank: 8.00 Boiler return temp: 1662 Output: 84,000 btuh

Return from tank: 165F Boiler output: 190

gpm tank: 8.00 Boiler return temp: 165 Output: 100,000 btuh

Return from tank: 168F Boiler output: 193

gpm tank: 8.00 Boiler return temp: 168 Output: 100,000 btuh

[break in data]

Final entry, as burn was ending and stack temp dropped to 350F:

Return from tank: 180F Boiler output: 190

gpm tank: 8.00 Boiler return temp: 180 Output: 40,000 btuh

Final tank temp: Top - 187F Bottom - 185F

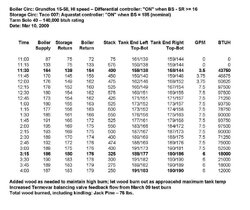

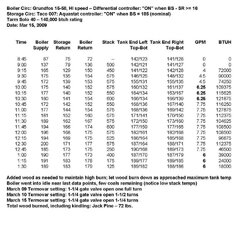

I changed my system over from a plate hx system to direct system operation. Reasons would be another discussion. I let the system cool down to depressurize for draining the boiler, which had antifreeze, and re-filling with water. Tank is horizontal 1000 gal LP. Piping is 1" steel between the boiler and tank. For this test the boiler was feeding only the storage, no other heat draw. I installed a flowmeter on the line to determine gpm.

The first interesting thing is the effect of the Termovar on boiler output to system vs feedback to boiler to maintain return temp. The data clearly shows that below about 150-155F system return to boiler, the Termovar is diverting substantial boiler output in the feedback loop back to the boiler, and as system return rises above this, the Termovar is diverting little if any boiler output in the feedback loop to the boiler. Initial boiler output to system was only 3 gpm at 96F system return to boiler, and boiler output to system maxed out at 8 gpm as system return to boiler reached about 155F.

The second interesting thing, although I did not record this for each data point, is actual Tarm output to system as related to stack probe temp. The burns during this data collection ranged between 400-500F stack temp (near the end, not included in data points, stack temps rose to 600F before coming back down). Stack temps closer to 500 produced the higher btuh outputs, and stack temps closer to 400 produced the lower btuh outputs. The Tarm is rated at 140,000 btuh, and the data shows that this can be reached only with stack temps above 500F.

A third interesting thing is effect of change in speed of the Grundfos UPS 15-58 on gpm's. My install is a bit unusual as I have the 15-58 on the boiler return, as normal, and I also have a Taco 007 on the tank return to the boiler, two circs operating to supplement each other. With the 007 shut down, but flow through the 007, 15-58 output was: Lo - 3.3 gpm, Med - 4.75 gpm, Hi - 5.50 gpm. With the 007 turned on, output was: Lo - 7.0 gpm, Med - 7.6 gpm, Hi - 8.0 gpm. All data shown below was with both circs on and the 15-58 on Hi.

A fourth interesting thing is that at gpm's below about 7, very little mixing was occurring in the horizontal tank and a high degree of stratification was occurring throughout the tank. As gpm's rose above 7, it was evident that mixing was increasing. I measured tank temp at both ends, top and bottom. For others with horizontal tanks, it may be important to keep the flow gpm's below 7 to achieve maximum stratification benefits. I have a diptube near the bottom of the tank for return to system, and supply to tank is about 1 foot from the diptube with a horizontal injection into the tank along the top and away from the diptube.

The last interesting thing is that during this entire test, the boiler did not idle at all. I continued the test past the data shown. My last data point collected is the final entry below. The absence of any idling maximizes boiler performance.

I fired the Tarm and let it come up to about 160F temp before turning on the circs.

Initial return from tank: 96F Boiler output: 160

gpm to tank: 3.0 Boiler return temp: 130 Output: 96,000 btuh

Return from tank: 130F Boiler output: 164

gpm tank: 6.25 Boiler return temp: 140 Output: 106,250 btuh

Return from tank: 134F Boiler output: 165

gpm tank: 6.75 Boiler return temp: 145 Output: 104,625 btuh

Return from tank: 137F Boiler output: 167

gpm tank: 7.50 Boiler return temp: 147 Output: 112,500 btuh

Return from tank: 142F Boiler output: 168

gpm tank: 7.75 Boiler return temp: 150 Output: 100,750 btuh

Return from tank: 148F Boiler output: 172

gpm tank: 8.00 Boiler return temp: 152 Output: 96,000 btuh

Return from tank: 153F Boiler output: 176

gpm tank: 8.00 Boiler return temp: 157 Output: 92,000 btuh

Return from tank: 156F Boiler output: 183

gpm tank: 8.00 Boiler return temp: 160 Output: 108,000 btuh

Return from tank: 159F Boiler output: 181

gpm tank: 8.00 Boiler return temp: 160 Output: 88,000 btuh

Return from tank: 162F Boiler output: 183

gpm tank: 8.00 Boiler return temp: 1662 Output: 84,000 btuh

Return from tank: 165F Boiler output: 190

gpm tank: 8.00 Boiler return temp: 165 Output: 100,000 btuh

Return from tank: 168F Boiler output: 193

gpm tank: 8.00 Boiler return temp: 168 Output: 100,000 btuh

[break in data]

Final entry, as burn was ending and stack temp dropped to 350F:

Return from tank: 180F Boiler output: 190

gpm tank: 8.00 Boiler return temp: 180 Output: 40,000 btuh

Final tank temp: Top - 187F Bottom - 185F