Garnzilla - The epic installation battle begins!

- Thread starter rvtgr8

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

BrownianHeatingTech

Minister of Fire

stihlwoody said:I was under the impression that taco pumps were to be mounted horizontally, not vertical?

Yup. That pump needs to rotate 90 degrees.

Also (to rvtgr8), the brass ball valve coming off the boiler supply should probably be further from the boiler. I'd put it as far as possible, just shy of the manifold.

Joe

stee6043

Minister of Fire

stihlwoody said:stee...

I was under the impression that taco pumps were to be mounted horizontally, not vertical?

Steve

Yes, and I proved this to be not just a suggestion! I ended up replacing my Taco pumps with Grundfos three speed units last month. After about 6 weeks of running in the wrong position both of my Taco pumps started to make noise. Neither of them gave up the ghost, but I replaced both nonetheless. The Grundfos pumps seem much better for the money in my opinion....

These are three speed Grundfos. I was told, maybe erroneously, that these could be mounted vertically. I did not see anything in my literature, but if I am wrong, now is the time to change it. The ball valve is almost seven feet away from the Garn on the supply side, while the return side is right at the manifold. Is this a deal breaker? I just got back from picking up my strainer wyes. I told my dog not to let anything go wrong while I was away... I knew I couldn't trust him. More feedback please! I am a glutton for redoing things!

Robert

Robert

BrownianHeatingTech

Minister of Fire

rvtgr8 said:These are three speed Grundfos. I was told, maybe erroneously, that these could be mounted vertically. I did not see anything in my literature, but if I am wrong, now is the time to change it.

No, you're fine. The thing that can't be vertical is the shaft of the pump (except under some very specific situations). As long as the shaft is horizontal, any orientation of the pump body is acceptable.

rvtgr8 said:The ball valve is almost seven feet away from the Garn on the supply side, while the return side is right at the manifold. Is this a deal breaker?

Not a deal breaker. But yellow metal should be as far as possible from the tank on a Garn, to reduce the level of galvanic corrosion. There will always be some, regardless of how far away it is, but the rate of corrosion drops off, the further the yellow metal is kept from the tank. Six or seven feet is "acceptable," but if you can manage it, further is better.

Joe

Thank you Joe. I really appreciate your knowledge and willingness to give rookies like me your input.

Rick Stanley

Feeling the Heat

Joe,

Generally speaking, would putting dielectric nipples on either side of a ball valve make distance from the tank, less of an issue? Or? How does that work? Do dielectric fittings accomplish the same thing as keeping yellow metal FAR from the tank?

Robert,

Looking good!! Must seem good to be actually putting things together. I'm glad for you. How far are your pumps off of the floor?

Generally speaking, would putting dielectric nipples on either side of a ball valve make distance from the tank, less of an issue? Or? How does that work? Do dielectric fittings accomplish the same thing as keeping yellow metal FAR from the tank?

Robert,

Looking good!! Must seem good to be actually putting things together. I'm glad for you. How far are your pumps off of the floor?

Here are some pictures to show recent progress. I have been building cold frames and improving my small greenhouse and so it has been slow going on the boiler.

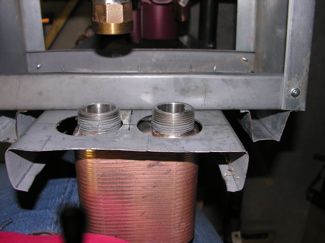

Picture 1 - This is my 50 plate HX

Picture 2 - HX with heat resistant rubber gasket to keep precious btu's from going away.

Picture 3 - Metal mounting bracket for HX and insulation filled cowl made from 18 ga. 2x8" steel stud.

Picture 4 - Sheet metal cowl to cover HX with insulation.

Pictures 5 & 6 - HX mounted on bracket.

Picture 7 - Cowl attached.

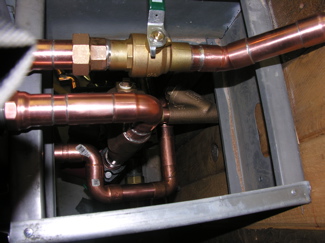

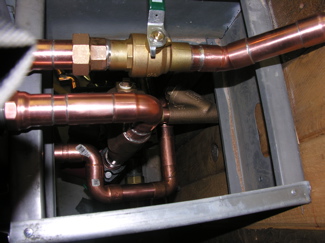

Pictures 8, 9 & 10 - Pipes, wye strainers, valves and unions reattached.

Any major flaws? Questions? Comments?

Fire away!

Robert

Picture 1 - This is my 50 plate HX

Picture 2 - HX with heat resistant rubber gasket to keep precious btu's from going away.

Picture 3 - Metal mounting bracket for HX and insulation filled cowl made from 18 ga. 2x8" steel stud.

Picture 4 - Sheet metal cowl to cover HX with insulation.

Pictures 5 & 6 - HX mounted on bracket.

Picture 7 - Cowl attached.

Pictures 8, 9 & 10 - Pipes, wye strainers, valves and unions reattached.

Any major flaws? Questions? Comments?

Fire away!

Robert

Sting,

Thanks for your kind words. I do try to keep my solder work clean. My hope is that that the inspector will cut me some slack for work that looks professional. Lord knows I need all the slack I can get. Even an average cook can make his food taste a little better if he feeds it to you on a pretty enough plate. :cheese:

Robert

Thanks for your kind words. I do try to keep my solder work clean. My hope is that that the inspector will cut me some slack for work that looks professional. Lord knows I need all the slack I can get. Even an average cook can make his food taste a little better if he feeds it to you on a pretty enough plate. :cheese:

Robert

I have a question. I am assuming pipe dope will work as well as teflon on the HX. I doped the male threads and the female threads in the connector as well. I turned the fitting by hand (4 turns) until it was no longer possible. I then took an 18" wrench and turned the fitting an additional 1.5 turns. I know I could have gon a bit farther but am afraid to put too much pressure on the HX. My question is simple, does this sound like it will sufficient to keep it from leaking?

Robert 8-/

Robert 8-/

WoodNotOil

Minister of Fire

rvtgr8 said:I have a question. I am assuming pipe dope will work as well as teflon on the HX. I doped the male threads and the female threads in the connector as well. I turned the fitting by hand (4 turns) until it was no longer possible. I then took an 18" wrench and turned the fitting an additional 1.5 turns. I know I could have gon a bit farther but am afraid to put too much pressure on the HX. My question is simple, does this sound like it will sufficient to keep it from leaking?

Robert 8-/

It will probably be fine. You will know if it is not though! I assume you put in unions and you have a way of isolating it. If it does leak, then isolate it, take it off, and tighten it. Sometimes it helps to heat the doped joint before trying to turn it. However, I don't see it being a problem.

W~O,

Thanks for the quick reply. The forum seems to have slowed a bit of late because of the return of spring. I hope it is going to hold, but I have isolated it and can redo it if necessary. As I have stated before on the site, I have plumbing skills, but what I don't know about hydronics could fill volumes. Thanks again.

Robert

Thanks for the quick reply. The forum seems to have slowed a bit of late because of the return of spring. I hope it is going to hold, but I have isolated it and can redo it if necessary. As I have stated before on the site, I have plumbing skills, but what I don't know about hydronics could fill volumes. Thanks again.

Robert

steam man

Minister of Fire

WoodNotOil said:rvtgr8 said:I have a question. I am assuming pipe dope will work as well as teflon on the HX. I doped the male threads and the female threads in the connector as well. I turned the fitting by hand (4 turns) until it was no longer possible. I then took an 18" wrench and turned the fitting an additional 1.5 turns. I know I could have gon a bit farther but am afraid to put too much pressure on the HX. My question is simple, does this sound like it will sufficient to keep it from leaking?

Robert 8-/

It will probably be fine. You will know if it is not though! I assume you put in unions and you have a way of isolating it. If it does leak, then isolate it, take it off, and tighten it. Sometimes it helps to heat the doped joint before trying to turn it. However, I don't see it being a problem.

The one weak link it seems in all the piping I have done is all the leaks from the copper threaded fittings. I tend to find they are poorer quality Chinese ones. The threads are generally terrible. Inspect them closely before use. We have discussed this before here and the ways to seal threaded joints. I find that using dope-tape-dope generally will keep leaks from happening (along with almost over-tightening). One thing I do is scour the fitting bins of some of the older stock I find in a few local stores to find good heavy American fittings that have been sitting sround for some time. The best part is they usually have never had any price adjustments. I buy all I can then. Good looking solder joints though.

That's my rant and rave for the day..........

Mike

BrownianHeatingTech

Minister of Fire

Rick Stanley said:Generally speaking, would putting dielectric nipples on either side of a ball valve make distance from the tank, less of an issue? Or? How does that work? Do dielectric fittings accomplish the same thing as keeping yellow metal FAR from the tank?

Will it probably help? Yes.

Is it worth risking, compared to adding a few feet of pipe? Not in my opinion...

Joe

sdrobertson

Minister of Fire

Bumping - Wondering how the install is going Robert? I'm enjoying following your install.

Shannon

Shannon

Thanks for the bump! I have been working on a number of projects in preparation for spring. My greenhouse and cold frames have been looking pretty spectacular. The weather was really making it hard for me to work inside but then.... because I was so thoughtless, because I washed my car and because I wanted to jump start my tomatoes, I caused a statewide blizzard. It dumped 20" of the heavy wet stuff on the Front Range. I used up most of the rest of my split firewood. I promise I won't let it happen again. Are you listening Mother Nature? I will get back to work on the boiler and split more wood...

On a more Hearth related issue, I have had to put in a couple of extra valves on my install because I am about to hook into the existing systems and I am worried about the soldering in of my new pipes. The moisture in the pipes really impacts my ability to get a good joint. Pictures to follow.

Robert

On a more Hearth related issue, I have had to put in a couple of extra valves on my install because I am about to hook into the existing systems and I am worried about the soldering in of my new pipes. The moisture in the pipes really impacts my ability to get a good joint. Pictures to follow.

Robert

slowzuki

Minister of Fire

Slow,

Thank you for contacting me. I had to take the summer and devote it to making greenhouses and a few other major projects. I have just returned to the install and am working furiously to get it finished before the snow flies. I got my county on board and am through most of the plumbing and steel framing. I have located my vermiculite and with any luck, I will be done in the next few weeks. My next project will be to build a HX for the indoor hot tub. I have a lot of pictures and will post in a few weeks.

Robert

Thank you for contacting me. I had to take the summer and devote it to making greenhouses and a few other major projects. I have just returned to the install and am working furiously to get it finished before the snow flies. I got my county on board and am through most of the plumbing and steel framing. I have located my vermiculite and with any luck, I will be done in the next few weeks. My next project will be to build a HX for the indoor hot tub. I have a lot of pictures and will post in a few weeks.

Robert

- Status

- Not open for further replies.