You are misreading the gravity loop in the Heatweb schematic. The loop turns down at the heat dump HX, short of the expansion tank, and does indeed put delta T to work. My manufacturer blesses a scheme that runs radiant right out of the boiler with mixing valves. (Obviously you could still have pressure problems in some pipe runs, but it is easy enough to put them on a heat exchanger.) All my manufacturer says about the gravity loop is that it should be as straight up as possible and that the run shouldn’t be longer than 19.5 feet, or 6 meters. That would be measured to the highest radiator rather than the expansion tank. The manufacturer of my stove wants a minimum water temperature of 113 degrees. I want an efficient fire most of all, so I can’t say what water temperature I’ll need with the hydronic pumps running—I am using a radiant slab as storage. The manufacturer suggests that much heat will be going up. It suggests a towel warmer as a heat dump radiator, and says it can be useful in the summer to dry towels. (Nope; I don’t believe that either.)

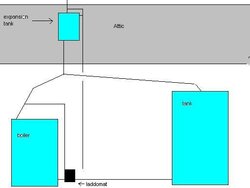

Well I just snagged a schematic off the heatweb site so that we can both be pointing at the same thing... It appears to me that all the schematics use variations on the same basic theme as the one I grabbed.

I see

two tanks

1. A large lower tank which they use for heat storage, putting the heat into it by either thermosiphon action, or by pumping.

2. An much smaller upper tank which they describe as a "feed and expansion tank", and in some drawings specify must have a water level 300mm (approx 12")

minimum above the highest radiator, and which contains the "toilet valve" fill mechanism - in each case the design incorporates elements that would work to keep heat from thermosiphoning into the expansion tank...

This is just what I said - the function of the expansion tank is to pressurise the system, not store heat or do anything else... In order to pressurise, it MUST be located at the highest point - which presumably would be in the attic or close to it. The boiler CAN be located anywhere in the system as long as it's below the expansion tank, but in order to get the maximum benefit from being pressurised, it needs to be located near where the pressure is highest, namely at the lowest point in the system...

Note that in the schematic I borrowed, they say there is a minimum height above the boiler that must be maintained - and to see the boiler specs for it. Also note that this is NOT a spacially accurate drawing, but rather a functional block diagram that shows the way the various parts interact...

While they do use the lower heat storage tank as part of the thermosiphon based heat dump in SOME of their layouts, it is by no means the only approach they use... The heat dump is a totally different function, and has no real effect on the expansion tank, other than that water expands when it's heated, and thus pushes the water level in the tank up.

I am confused :-S it seems like you are saying that I'm wrong, and that the correct understanding is what I just said that was wrong???

[/quote]Yes, my stove is a blunter instrument than a gasifier. It is also very different in the fact that it’s 20 feet away rather than in the backyard. Even so, I’d look hard at the Brits’ belt and suspenders approach even if I was putting a wood boiler in the basement. Recall that this thread began with the state of Michigan’s willing to bless a system that boils rather than blows up. Why stop there?[/quote]

Actually, if you go back to the beginning of the thread, you will find that

I was the one who started it, and talking about the state of

Massachusetts (MA, not MI) having rules requiring an ASME approval on a boiler, not a willingness to accept a system that boiled (though that is (barely) more acceptable than blowing up...) However I think Michigan may be one of the other states that is also having a similar problem, so your confusion is understandable.

While many people do put gasifiers in outbuildings, most are actually designed to be put in basements, and if I ever do my system, that's where mine will go - indeed I would be spending most of my time far closer than 20' from the boiler, as it would be ending up in the room directly under my office...

I do agree with you about looking at the British approach, but my feeling is that while they have some excellent ideas (which I plan to incorporate) some of them are not so good in that their "failure mode" is barely any better than the failure it is intended to counter... IMHO a flood caused by that toilet valve trying to refill the system after a line break somewheres else is not an acceptable fix... What I would choose instead is some form of level switch on the tank that would trip a "low water alarm" if the tank level dropped too much, and cause the system to go into "shutdown mode" (shut off air, turn off all circs, maybe close all zone valves, etc) and have a seperately autocontrolled emergency dump zone and / or cold water dump through boiler to drain to deal with any resulting boiler overheat - same net result, without making the flood worse...

Gooserider

!

! reat_ if the federal government enacted a standard that gave any boiler meeting the specified Euro standards "reciprocity" under certain US standards- and declared that reciprocity as pre-empting any state or local standard to the contrary. That'd really pave the way for introduction of innovation, which we need (side note, I am a happy Econoburn owner, and the E-burn does meet US standards, and can be had with an ASME stamp- I just think that it'd be good to really get this technology "out there" as far and wide and fast as reasonably possible) Of course, I am not a congressperson, so I have no ability to spur such federal action-- just noting that it's potentially possible from a legal/ technical standpoint if the right constituencies could built an appropriate head of steam behind it....

reat_ if the federal government enacted a standard that gave any boiler meeting the specified Euro standards "reciprocity" under certain US standards- and declared that reciprocity as pre-empting any state or local standard to the contrary. That'd really pave the way for introduction of innovation, which we need (side note, I am a happy Econoburn owner, and the E-burn does meet US standards, and can be had with an ASME stamp- I just think that it'd be good to really get this technology "out there" as far and wide and fast as reasonably possible) Of course, I am not a congressperson, so I have no ability to spur such federal action-- just noting that it's potentially possible from a legal/ technical standpoint if the right constituencies could built an appropriate head of steam behind it....