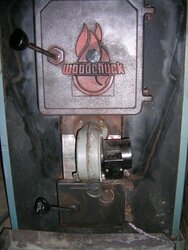

Has anyone ever cut a hole in their furnace door and added glass or heard of anyone doing it? I wouldn't think it would be all that difficult to do if you have the right materials and would certainly be nice to be able to look at your fire without opening the door.

Putting glass in door

- Thread starter freeburn

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

There was some talk about putting a viewing glass in the lower chamber door of a gasifier several months back and I am sure there was one for replacing a broken glass about that time as well. Seems if you have the skill and materials that it could be done. I wouldn't ry it unless I had a spare door and by saying that I guess I just exposed my skill level. You could probably go to a place that sells stoves with viewing glass and order the parts. (???)

muncybob

Minister of Fire

laynes69

Minister of Fire

There are 2 things that come to mind when modifying a door. One is you need cast iron, so it won't warp, break and cause a runaway fire. Second you need an airwash to keep the glass clean. If you don't have an airwash, your glass will become dirty right away. You will need a ceramic glass, which is expensive and if it doesn't work you need another door.

http://arboristsite.com/showthread.php?t=77617&highlight=putting+glass+door

http://arboristsite.com/showthread.php?t=85922&highlight=glass+door

Or a better option, buy a new woodfurnace and retire that old smoke dragon, but I know its not cheap!

http://arboristsite.com/showthread.php?t=77617&highlight=putting+glass+door

http://arboristsite.com/showthread.php?t=85922&highlight=glass+door

Or a better option, buy a new woodfurnace and retire that old smoke dragon, but I know its not cheap!

That is hilarious. I'm sure my wife will agree to that. "Hey, where are you going with my pie pan." "Well, you don't need it, there's no pie in it, so I'm going to look at my fire through it." Yeah, that'll fly. But it's a good thought. I thought about taking an old stove glass and just holding it up over the door.

Actually, what I'm trying to do now is find out when to turn off the main draft air, and let the secondaries kick in. I added a secondary burn tube to my wood chuck without modifying anything on the furnace. I got the idea from the Energy King 385. My secondary air starts where a 1.5" black pipe fits perfectly through the manual damper in the ash door (also has option of being completely closed off) so that I can open and close the door without much hassle at all. It proceeds through a 90* pipe through the ash grate (it was an old one that was already destroyed) which is covered with firebrick (got that idea from the EPA stoves and ESW Add-on). Then another 90* with 1 more 1.5" pipe with holes drilled in it at the top of the stove underneath the secondary heat exchanger. Maybe I'll post pics. I can't believe I didn't think of it earlier, but I guess I needed to see how the 385 did it to get the idea. The whole thing only cost $25 and 30 min. to drill and install. Pretty simple. Now, I wait to see how/if it will work. It should, it pulls smoke through it, without heating up the chimney at all. I'll have to wait until it gets a little colder to really try it out. Don't worry I beefed up the inside with firebrick pretty much everywhere.

Does anyone know when to turn off the main draft? Can you base it on time, or do you have to be able to see the fire to know?

Actually, what I'm trying to do now is find out when to turn off the main draft air, and let the secondaries kick in. I added a secondary burn tube to my wood chuck without modifying anything on the furnace. I got the idea from the Energy King 385. My secondary air starts where a 1.5" black pipe fits perfectly through the manual damper in the ash door (also has option of being completely closed off) so that I can open and close the door without much hassle at all. It proceeds through a 90* pipe through the ash grate (it was an old one that was already destroyed) which is covered with firebrick (got that idea from the EPA stoves and ESW Add-on). Then another 90* with 1 more 1.5" pipe with holes drilled in it at the top of the stove underneath the secondary heat exchanger. Maybe I'll post pics. I can't believe I didn't think of it earlier, but I guess I needed to see how the 385 did it to get the idea. The whole thing only cost $25 and 30 min. to drill and install. Pretty simple. Now, I wait to see how/if it will work. It should, it pulls smoke through it, without heating up the chimney at all. I'll have to wait until it gets a little colder to really try it out. Don't worry I beefed up the inside with firebrick pretty much everywhere.

Does anyone know when to turn off the main draft? Can you base it on time, or do you have to be able to see the fire to know?

pybyr

Minister of Fire

I've seen woodstoves with pie plate doors- but I'd suggest never doing anything that could interfere with the spontaneous flow of pie!

Supposedly some of the Tarm gasification boilers have a "sight glass" in the lower door- see page 2, item 6 here- maybe you could order and adapt in one of those?

www.woodboilers.com/userfiles/file/SoloInnovaDataSheet.pdf

Supposedly some of the Tarm gasification boilers have a "sight glass" in the lower door- see page 2, item 6 here- maybe you could order and adapt in one of those?

www.woodboilers.com/userfiles/file/SoloInnovaDataSheet.pdf

laynes69

Minister of Fire

With my old furnace, I would take it to around 500 to 550 then dampen in down. This got the firebox hot enough to allow for secondary air to burn off some smoke. After loading for the night, I would wait around 20 to 25 minutes then damper down. You need enough air flow to burn off all secondaries. Your best bet would be to watch your chimney. You want your wood charred some before dampening it down.

laynes69 said:With my old furnace, I would take it to around 500 to 550 then dampen in down. This got the firebox hot enough to allow for secondary air to burn off some smoke. After loading for the night, I would wait around 20 to 25 minutes then damper down. You need enough air flow to burn off all secondaries. Your best bet would be to watch your chimney. You want your wood charred some before dampening it down.

Thanks, that's exactly what I was looking for. Now I can keep my cast iron door which I would rather (safer) do. One quick clarification, is the 500/550 stack/pipe temp, or the furnace itself (say on the front). Maybe they are the same by that time.

Badfish740

Minister of Fire

- Oct 3, 2007

- 1,539

Somebody did it on a Hot Blast over at Arboristsite. They did a pretty nice job from the pictures I saw-not sure where they got the glass though. If you do a search for "glass door hot blast" you should find it.

laynes69

Minister of Fire

fabguy01

New Member

Badfish740

Minister of Fire

- Oct 3, 2007

- 1,539

fabguy01 said:you should be able to find something that will work here http://www.mcmaster.com/#glass/=3od6zh

If I ever win the lottery (as in tens of millions) I'll become McMaster-Carr's best customer.

How about stove mica glass/eisenglass/isinglass or however you spell it? What if I were to use that cut a circle of mica and use a black pipe nipple in the door, not exactly sure how I would fit it, but I just want a sight glass. Any ideas as to how I could do that? I have a 3 x 5 piece of Mica.

Gooserider

Mod Emeritus

There were a couple of smoke dragon designs that used pie plates back in the pre-EPA days, I don't know of any that do so today. Modern stove windows use a special high temp ceramic that is VERY expensive, but also very tough and heat resistant. PyroCeram is one brand, I think there are a couple of others.

I would be very hesitant about modifiying a door, especially in the lower gassification chamber as I'd be worried about the ability of the window to stand up to the higher than woodstove temperatures, and the possible change in the heat flows of the boiler. However if I was to do so, I would definitely be looking at that PyroCeram, and nothing else.

Gooserider

I would be very hesitant about modifiying a door, especially in the lower gassification chamber as I'd be worried about the ability of the window to stand up to the higher than woodstove temperatures, and the possible change in the heat flows of the boiler. However if I was to do so, I would definitely be looking at that PyroCeram, and nothing else.

Gooserider

pybyr

Minister of Fire

Gooserider said:There were a couple of smoke dragon designs that used pie plates back in the pre-EPA days, I don't know of any that do so today. Modern stove windows use a special high temp ceramic that is VERY expensive, but also very tough and heat resistant. PyroCeram is one brand, I think there are a couple of others.

I would be very hesitant about modifiying a door, especially in the lower gassification chamber as I'd be worried about the ability of the window to stand up to the higher than woodstove temperatures, and the possible change in the heat flows of the boiler. However if I was to do so, I would definitely be looking at that PyroCeram, and nothing else.

Gooserider

Completely agreed about needing to use some sort of special high temp material, about being careful not to introduce unintended dynamics of flow of heat or hot gases-- but I do think I recall seeing some literature of some model of Tarm downdraft gasifier that had a tiny clear observation port by which one could observe and adjust what was going on in the lower chamber- seems like an appealing but not essential feature-seems like if you open the door to observe, you're almost certainly changing the variables that affect what's going on. Nofo's methods of attaining temp measurements of what's going on inside seem like they probably far exceed the precision of anything one could glean by visuals.

pybyr said:Nofo's methods of attaining temp measurements of what's going on inside seem like they probably far exceed the precision of anything one could glean by visuals.Gooserider said:There were a couple of smoke dragon designs that used pie plates back in the pre-EPA days, I don't know of any that do so today. Modern stove windows use a special high temp ceramic that is VERY expensive, but also very tough and heat resistant. PyroCeram is one brand, I think there are a couple of others.

I would be very hesitant about modifiying a door, especially in the lower gassification chamber as I'd be worried about the ability of the window to stand up to the higher than woodstove temperatures, and the possible change in the heat flows of the boiler. However if I was to do so, I would definitely be looking at that PyroCeram, and nothing else.

Gooserider

I'm not trying to do anything with a gassification boiler, all I have is a woodchuck 526 warm air furnace, and all I wanted to do was add a viewing window in the door so I could see if/when my secondaries were kicking in.

I don't have a gassification boiler, just a wood furnace. I just want to see what's going on inside the burn chamber, not below. Who is Nofo (No Fossil)? What are his methods?

pybyr

Minister of Fire

jburner said:pybyr said:Nofo's methods of attaining temp measurements of what's going on inside seem like they probably far exceed the precision of anything one could glean by visuals.Gooserider said:There were a couple of smoke dragon designs that used pie plates back in the pre-EPA days, I don't know of any that do so today. Modern stove windows use a special high temp ceramic that is VERY expensive, but also very tough and heat resistant. PyroCeram is one brand, I think there are a couple of others.

I would be very hesitant about modifiying a door, especially in the lower gassification chamber as I'd be worried about the ability of the window to stand up to the higher than woodstove temperatures, and the possible change in the heat flows of the boiler. However if I was to do so, I would definitely be looking at that PyroCeram, and nothing else.

Gooserider

I'm not trying to do anything with a gassification boiler, all I have is a woodchuck 526 warm air furnace, and all I wanted to do was add a viewing window in the door so I could see if/when my secondaries were kicking in.

Who is Nofo? What are his methods?

Nofossil- one of the top tech & measurement masters here in the Boiler Room (and all around ingenious and helpful person) see, as an example-

https://www.hearth.com/econtent/index.php/forums/viewthread/13587/

and you can look at much useful and interesting info on his website:

http://www.nofossil.org

And to be able to see if the secondary air works, I also added a sight glass at a cost of $5 for the mica glass, of which I have a spare lens in case this one gets punched through. It's flimsy stuff, but will withstand the heat.

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 804

- Replies

- 0

- Views

- 320

- Replies

- 8

- Views

- 410