A micronizer doesn’t really care what the pressure is. It only works when the volume of water is sufficient to cause a pressure differential across the device, so the venturi can draw in air. The higher the presser, the less volume your pump produces. When the pressure gets high enough, and the volume from the pump gets low enough, the micronizer no longer draws in air.

A larger well pump that produces more volume at higher pressure would make the micronizer work from 30 PSI, all the way up to 50 PSI. However, this will cause the well pump to cycle on and off excessively, because your pump will then produce much more volume than you are using.

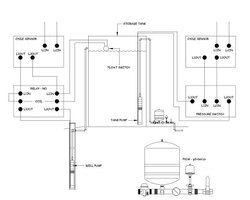

Adding a Cycle Stop Valve to a larger well pump will keep the pressure constant and prevent the pump from cycling. Although when the system gets up to the pressure held constant by the CSV, the volume of water produced will be determined by the amount being used at that time.

In other words, with a 30/50 pressure switch, and the CSV set for 45 PSI, the tank will drain from 50 to 30 when water is first used. Then when the pump starts at 30 PSI, the volume produced by the pump will be at maximum, and the micronizer will be working until the pressure gets to 45 PSI. At that point the CSV will restrict the volume from the pump to match the amount being used. If the house is using enough water, the micronizer will continue to draw in air. If the house is not using enough water, the micronizer will not be drawing in air. If the house is no longer using any water at that point, the CSV will restrict the flow from the pump to 1 GPM, and the pressure tank will be topped off from 45 to 50 PSI, and the pump will be shut off.

This normally works ver well, as the first 3/4 of the tank is filled at high enough volume to make the micronizer draw in air. Then the CSV tops off the last 1/4 of the tank at 1 GPM and the pump shuts off. For intermittent uses around the house such as showers, washing machines, toilets, etc., this adds sufficient air to make the system work properly. When there are long term uses of water that are more than 1 GPM, such as sprinklers, the CSV will match the volume being used, and wether the micronizer is drawing in air or not depends on how much water the sprinklers are using. You just have to use enough sprinklers at one time to make the micronizer function.

30/50 is very low pressure for a house, especially when running through a filter. I agree 60 PSI constant would be much better. However, you will need a larger pump that can produce enough volume for the micronizer to work at the higher pressure. Then having a CSV to maintain constant pressure and keep the pump from cycling during long term uses of water becomes more important. With a larger pump, I would set the pressure switch to 45/65, and set the CSV to 60 PSI constant.

A booster pump after the pressure tank could increase the house pressure but, will not increase the volume through the micronizer. Increasing the size of the well pump will do both. Either way I do not recommend the MQ for a booster. I find dumpsters full of these behind the pump supply houses because they have so many problems. (See attached picture) If you need a booster, a regular jet pump is more dependable, longer lasting, and less expensive.