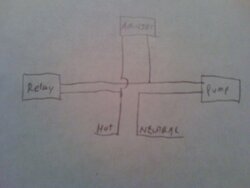

I'm in the process of building a controller for my Tarm to run the pump, air handler, and overheat situations (dump zone, air handler). I have a solid state relays that will basically be replacing the aquastats I have in place. Initially I want to keep the aquastats in the system in case the controller, or my programming, craps out. If I have the relay / aquastat / pump wired parallel as below, when the aquastat turns on, there will be a 'hot' wire on both sides of the relay. Will this cause a problem with the relay? I'm planning on setting the aquastat temps for overheat only situations, so the relay should be on before the aquastat, but I'm only going to run the pump if the boiler supply is a set temp above the temp coming out of the air handler, so there is a chance that the relay will be off when the aquastat is on.

Controller / Relay question

- Thread starter twitch

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.