Well I added 300 gallons of storage this summer and had a test firing last night. Only 20 degrees outside over night.

After 14 hours I had 90* water on all 7 gauges ( gauges spread all over )

Almost a complete burn a few embers still glowing but no reconizable wood.

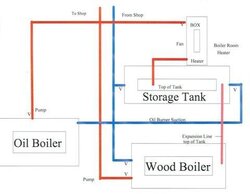

The storage tank (old HHO tank ) has 3 of the gauges on end wall.

When starting from a cold OWB at one time I had 180* water at top of wood boiler and 80* water on the lower supply outlet.

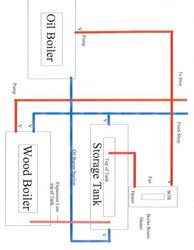

Here is what I did to add the storage.

The oil burner is in the loop put not fired up yet.

After 14 hours I had 90* water on all 7 gauges ( gauges spread all over )

Almost a complete burn a few embers still glowing but no reconizable wood.

The storage tank (old HHO tank ) has 3 of the gauges on end wall.

When starting from a cold OWB at one time I had 180* water at top of wood boiler and 80* water on the lower supply outlet.

Here is what I did to add the storage.

The oil burner is in the loop put not fired up yet.