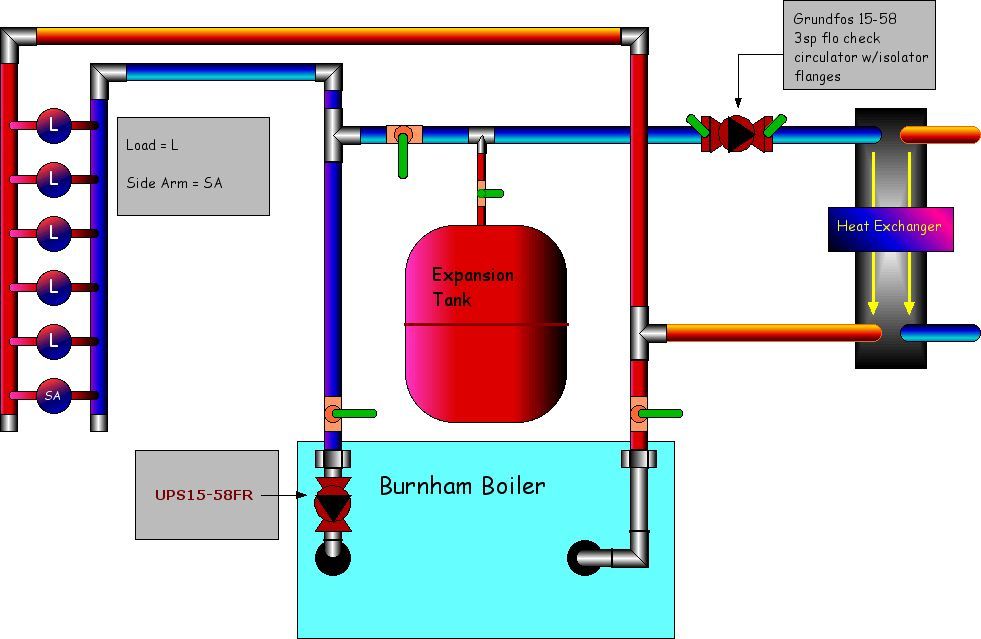

I have it all piped in and ready to go, but I am still without an adequate control strategy. I originally purchased a Tekmar 356 for use on a on a mixing valve. I no longer am utilizing the mix valve idea and it does not appear that I can use the 356 in my control scheme. If I am wrong I would appreciate a heads up. If I am right, I will let it go at a bargain. My problem is not unique. I want my Garn to be the main heat source unless for some reason the temperature in its water supply drops below a certain point. In that case, if I get a heat call from the system, I want the propane ($$$$$) boiler to become the main source until I get the Garn heated back up to a useful temperature range.

I have seen some members using off-the-shelf controls. Unfortunately for me, most of those controls are in the $600 + range, well beyond my fiscal reach.

I have seen some members build their own control systems. While they have impressed me with their resourcefulness, intelligence, and frugality, these members must have to shell out a fortune to modify the doors in their homes so they can get their giant brains from room to room. My doors appear to need no modification at this point.

I am nearing the end of my money allotted for my project and cannot afford to hire a HVAC engineer to help me over this last hurdle. So, I need advice. Can anyone point me in the right direction on some literature for me to build my own? Can anyone figure a way for me to modify the uses of the Tekmar 356 to suit my purposes? Can someone help me figure a way to develop a manual switchover so I can use the system until I can afford a more expensive solution?

I have seen some members using off-the-shelf controls. Unfortunately for me, most of those controls are in the $600 + range, well beyond my fiscal reach.

I have seen some members build their own control systems. While they have impressed me with their resourcefulness, intelligence, and frugality, these members must have to shell out a fortune to modify the doors in their homes so they can get their giant brains from room to room. My doors appear to need no modification at this point.

I am nearing the end of my money allotted for my project and cannot afford to hire a HVAC engineer to help me over this last hurdle. So, I need advice. Can anyone point me in the right direction on some literature for me to build my own? Can anyone figure a way for me to modify the uses of the Tekmar 356 to suit my purposes? Can someone help me figure a way to develop a manual switchover so I can use the system until I can afford a more expensive solution?