Westchoper

New Member

Andrew,

I thought I might be alone in building a pellet room in our basement to fill our Tarm 2.5 but was very glad to see your post. Congratulations on getting this project done in a weekend. Our room took much longer than my Dad and I expected to build. I think we share similar motivations, and I believe that bulk delivery is an important part of the pellet boiler being integrated in our heating system. Today, we have limited delivery options along the coast of Maine but I expect by next spring there will be multiple options to shop from. Our pellet room measures inside 11'4" x 8' x 10'3" with a 3' high sloped floor feeding a Chore-time flex auger. I've calculated about 11.5 tons capacity. I'm waiting for the auto fill device from Bioheat as that is a pricey option. Maybe we can get that for next season. I was warned by the auger supply people to build a robust room so this is a bit over built but the floor loads are pretty high for this storage quantity. Ours is made with 2 x 8 walls 12" OC and 3/4" Advantex T/G flooring for all surfaces except for the ceiling. The exterior of the walls will be either 1/2" Advantex in the boiler room or sheetrock. I had to build the floor elevated to make room for the auger lower boot so it took a bit of planning to get this done. All is good now, I'm just loading the 10 tons of bagged pellets from our garage storage to the new room. Thank goodness our house has a daylight basement and I can move the pallets with my tractor. Once that's done I'll be finished moving bags. The auger will move about 100 lbs of pellets per minute which I think will make loading the boiler quite simple.

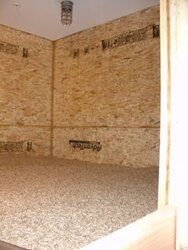

Here are some pictures of the project with about 90% complete and 5 tons loaded. I only wish I was closer to the pellet mills like you are.

Mark

I thought I might be alone in building a pellet room in our basement to fill our Tarm 2.5 but was very glad to see your post. Congratulations on getting this project done in a weekend. Our room took much longer than my Dad and I expected to build. I think we share similar motivations, and I believe that bulk delivery is an important part of the pellet boiler being integrated in our heating system. Today, we have limited delivery options along the coast of Maine but I expect by next spring there will be multiple options to shop from. Our pellet room measures inside 11'4" x 8' x 10'3" with a 3' high sloped floor feeding a Chore-time flex auger. I've calculated about 11.5 tons capacity. I'm waiting for the auto fill device from Bioheat as that is a pricey option. Maybe we can get that for next season. I was warned by the auger supply people to build a robust room so this is a bit over built but the floor loads are pretty high for this storage quantity. Ours is made with 2 x 8 walls 12" OC and 3/4" Advantex T/G flooring for all surfaces except for the ceiling. The exterior of the walls will be either 1/2" Advantex in the boiler room or sheetrock. I had to build the floor elevated to make room for the auger lower boot so it took a bit of planning to get this done. All is good now, I'm just loading the 10 tons of bagged pellets from our garage storage to the new room. Thank goodness our house has a daylight basement and I can move the pallets with my tractor. Once that's done I'll be finished moving bags. The auger will move about 100 lbs of pellets per minute which I think will make loading the boiler quite simple.

Here are some pictures of the project with about 90% complete and 5 tons loaded. I only wish I was closer to the pellet mills like you are.

Mark