Seems like everyone is in agreement that the best way to efficient hydronic heating with wood boilers is through low temperature emitters. Be it adding more fintube, replacing fintube with panel radiators, adding panel radiators to existing heating systems, or installing in floor radiant heat.

Pressurized or non-pressurized storage will both benefit on utilizing lower temperatures

Like gooserider says, maybe we can get some real pros in this field to help us out.

Slantfin's hydronic explorer program can easily tell you how many feet of fintube is required per room (to add) at the desired boiler temperature.

Pressurized or non-pressurized storage will both benefit on utilizing lower temperatures

Like gooserider says, maybe we can get some real pros in this field to help us out.

Slantfin's hydronic explorer program can easily tell you how many feet of fintube is required per room (to add) at the desired boiler temperature.

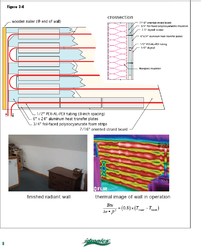

Most installers do the lower 3 feet to stay away from wall hanging anchors.

Most installers do the lower 3 feet to stay away from wall hanging anchors.