Help, I find myself involved in a renovation project for a Non-Profit. I may be slipping in over my head.

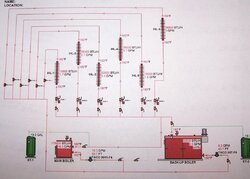

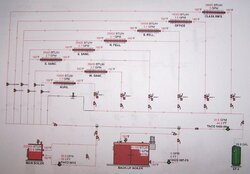

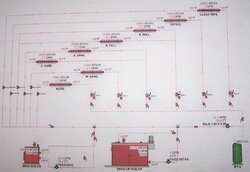

There are 6 zones of Radiant Base Board with head and GPM as follows:

Zone 1 - 16' at 2.00 gpm

Zone 2 - 25' at 2.64 gpm

Zone 3 - 29' at 5.28 gpm

Zone 4 - 24' at 3.60 gpm

Zone 5 - 21' at 1.80 gpm

Zone 6 - 28' at 2.88 gpm

2 Boilers piped parallel with the load in series. Main Boiler 2,000,000 btu has a TACO 0011-F4, Back-up boiler 80,000 btu TACO 007-F5. No pressure bypass valve in system.

I am asking if all the zone valves are open than I need a pump capable of 17.88 gpm at the highest zone head of 29. Is this correct? If so the 0011 will never move enough water and the 007 will do nothing.

It looks to me like I have to replace the main boiler pump with a TACO 1400-45 and re-pipe the Back-up boiler into the main boiler loop using two closely placed T's. The 1400-45 must run regardless of which boiler is in operation and the 007 will pump back-up boiler HW into Main boiler loop. Seems to be cheapest fix. Any ideas?

Also add a pressure bypass valve for when 5 zones are closed or add variable speed pump with delta T.

Are there any variable speed pumps with 29' head at 18 gpm?

Thanks for any assistance!

There are 6 zones of Radiant Base Board with head and GPM as follows:

Zone 1 - 16' at 2.00 gpm

Zone 2 - 25' at 2.64 gpm

Zone 3 - 29' at 5.28 gpm

Zone 4 - 24' at 3.60 gpm

Zone 5 - 21' at 1.80 gpm

Zone 6 - 28' at 2.88 gpm

2 Boilers piped parallel with the load in series. Main Boiler 2,000,000 btu has a TACO 0011-F4, Back-up boiler 80,000 btu TACO 007-F5. No pressure bypass valve in system.

I am asking if all the zone valves are open than I need a pump capable of 17.88 gpm at the highest zone head of 29. Is this correct? If so the 0011 will never move enough water and the 007 will do nothing.

It looks to me like I have to replace the main boiler pump with a TACO 1400-45 and re-pipe the Back-up boiler into the main boiler loop using two closely placed T's. The 1400-45 must run regardless of which boiler is in operation and the 007 will pump back-up boiler HW into Main boiler loop. Seems to be cheapest fix. Any ideas?

Also add a pressure bypass valve for when 5 zones are closed or add variable speed pump with delta T.

Are there any variable speed pumps with 29' head at 18 gpm?

Thanks for any assistance!