Was refereed to this site form another forum. And wow, I spent a good chunk of time today reading through threads here new and old. So I think its the perfict place to drop this bomb of a project.

I researching and getting ready to build next spring a 40x60 pole/steel building. To use as half shop half apartment and expect it to be used this way for ten years min. I am dead set on running radiant heat in the slab to do my primary heating. I currently have a quadrafire 3100 wood stove that will be installed for additional heating if needed. The problem I'm having is what type of wood burning apparatus I should use. I've looked everywhere and am starting to nail it down to a few options that I like. First is CB's new E-series gasification boiler. CB is mainly the only owb sold locally. While it is set up like a traditional owb it still is a hungry beast. On the other end of the spectrum I'm really falling for the Garn gasification boilers. Fundamentally it just makes sense from build quality, maintenance, efficiency. Price realy is really pretty close on these units. But the way they opportune makes me lean towards the garn the most.

To be honest I'm not one to follow the go green movement. And find the lifestyle a little wacky. But I am for saving money over time using practical inventions. The garn is one of them. The more I look at it and what people have done with them. I get more intrigued on what I can do to save a buck. Obviously I'd be using it to heat the radiant floor. But would like to use it as the primary water heat source for the entire year. As I really don't mind cutting wood, actually enjoy it quite a bit. And have cut, split and stacked 6 cords of oak and another 6 cords of mixed wood off my property. Should be dry and seasoned for winter of 2010.

So, what size garn do i need to heat 40x60 with 14' ceiling?

I know very little about designing a system. If you could, how would you set up this system?

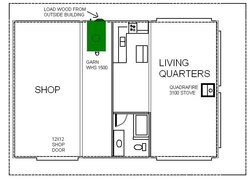

Also I drew up a quick sketch of the building and where I want the garn. And I agree with a few others that I do not want to store wood inside. To may critters/bugs to deal with. So I thought why not put the door out the side of the building for ease of storing and loading wood?

Only problem with that Idea is that the exhaust has to go some where. Can the exhaust be vertical instead of horizontal?

I researching and getting ready to build next spring a 40x60 pole/steel building. To use as half shop half apartment and expect it to be used this way for ten years min. I am dead set on running radiant heat in the slab to do my primary heating. I currently have a quadrafire 3100 wood stove that will be installed for additional heating if needed. The problem I'm having is what type of wood burning apparatus I should use. I've looked everywhere and am starting to nail it down to a few options that I like. First is CB's new E-series gasification boiler. CB is mainly the only owb sold locally. While it is set up like a traditional owb it still is a hungry beast. On the other end of the spectrum I'm really falling for the Garn gasification boilers. Fundamentally it just makes sense from build quality, maintenance, efficiency. Price realy is really pretty close on these units. But the way they opportune makes me lean towards the garn the most.

To be honest I'm not one to follow the go green movement. And find the lifestyle a little wacky. But I am for saving money over time using practical inventions. The garn is one of them. The more I look at it and what people have done with them. I get more intrigued on what I can do to save a buck. Obviously I'd be using it to heat the radiant floor. But would like to use it as the primary water heat source for the entire year. As I really don't mind cutting wood, actually enjoy it quite a bit. And have cut, split and stacked 6 cords of oak and another 6 cords of mixed wood off my property. Should be dry and seasoned for winter of 2010.

So, what size garn do i need to heat 40x60 with 14' ceiling?

I know very little about designing a system. If you could, how would you set up this system?

Also I drew up a quick sketch of the building and where I want the garn. And I agree with a few others that I do not want to store wood inside. To may critters/bugs to deal with. So I thought why not put the door out the side of the building for ease of storing and loading wood?

Only problem with that Idea is that the exhaust has to go some where. Can the exhaust be vertical instead of horizontal?

No need to leave it bare, just use less on the side facing the room.

No need to leave it bare, just use less on the side facing the room.