Hi all, I recently joined the forum due to a feed problem on my pellet stove insert. It is a Whitfield Advantage manufactured in Oct 1994, according to the stamped label on the unit. The auger was not turning and I finally found the info to check the pressure switch on the combustion motor. When I disconnected the orange hose at the switch the auger turned. So, I have now determined from the info on this forum (thank you for all the info you have provided!) and other sites that the problem is the flue is clogged. The funny thing is I am convinced it is full of stink bugs. They have infested the area I live in to the point my house is covered with them in the fall, I mean hundreds if not thousands of the buggers. A friend that lives close by had a chimney full of them when she did the sweeping this fall. Anyway, my problem is I cannot figure out how to open the bottom of the clean out tee. I feel foolish asking, I have seen where the bottom is supposed to screw off but no matter what I do nothing moves. I just don't want to break anything. There is a bit of the rubber sealant in the area so I don't know if it was sealed on for good with this at install. I'm thinking there might be a screw where that black hole is at the bottom, it is covered with the rubber sealant. I can also tell the sealant has separated from the joint where the stove (combustion motor) joins the clean out tee. I have the RTV silicone sealant so I will reseal the joint. I have the stove about half way out of the fireplace, enough to open the T up and vacuum what I can out of there. What would be the best way to go about getting the flue opened up to clean out the bugs and ash?

Pellet stove clean out T

- Thread starter rushhourscreen

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Smudge88

Member

The best way to try to get the cleanout cap off is with a strap wrench... can pick one up at a plumbing supply or maybe even Home Depot or Lowes. From the looks of that Tee you might be better off taking the sawsall to it and buying a new one. Good luck....

Thanks for responding! I do have a strap wrench and tried it but nothing moved. Do you mean a whole new clean out tee? Just curious why do you say that? I'm new at this and want to learn. thanks.

I

imacman

Guest

At this point, I think you need to clean the silicone out of that hole, and see if there's a screw in there securing the cap. Is there another one on the opposite side too?

If you can't get it open, there's no way to clean the pipe short of disconnecting it from the stove somehow.

If you can't get it open, there's no way to clean the pipe short of disconnecting it from the stove somehow.

jtakeman

Minister of Fire

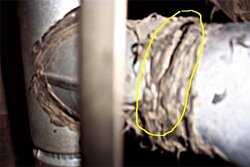

Actually that tee looks to be an older one where the cap is just a tin plug at the bottom. You can pry it out with a screw driver. Most of them are sealed with silicone. May need to work at it some. Snap a picture looking at the bottom so we can be sure.

Also looking at it where the tee connects to the stove there is a gap that you should try to reseal with hi temp silicone or tape with hi heat aluminum tape.

Also looking at it where the tee connects to the stove there is a gap that you should try to reseal with hi temp silicone or tape with hi heat aluminum tape.

thanks everyone. The plate at the bottom is what I was thinking but I wasn't sure. I tried the screwdriver earlier but I'm going to go try again. I'll let you know.

jtakeman

Minister of Fire

I

imacman

Guest

jtakeman said:Please be sure to reseal this area! This is a good chance for a leak and smoke smell in the house! Do it now while you are there messing with it!

Good idea jay. However, from the looks of that pipe and the silicone gobbed on it, I think it should be scraped off and done over....I know it's a PIA to do, but that mess doesn't look good at all.

Plus, once removed, hopefully he could get the pipe apart and see what he's dealing with inside.

jtakeman

Minister of Fire

macman said:jtakeman said:Please be sure to reseal this area! This is a good chance for a leak and smoke smell in the house! Do it now while you are there messing with it!

Good idea jay. However, from the looks of that pipe and the silicone gobbed on it, I think it should be scraped off and done over....I know it's a PIA to do, but that mess doesn't look good at all.

Plus, once removed, hopefully he could get the pipe apart and see what he's dealing with inside.

It is definitely a big mess. Smudge88 might have the right idea scrap it and start fresh. At least to the liner anyway. Tee, appliance adapter and liner adapter can't be more than $80.00 or so.

charles u farley

New Member

How long have you had the stove? Have you ever pulled out the sheet metal ash trap baffles behind the fire bricks and thoroughly cleaned behind them and the passage leading to the exhaust blower?

Skippydo

New Member

I'll tell you what I did, and it eliminates all the detail of cleaning and removing the T.

I took my vac, put the end of the hose to the middle of the T, traced a hole a little

bigger so I could get my cleaning rod in the hole and drill a hole, put my saw

blade in and cut a hole in 15 seconds. I can now put in the brush and then the

end of the vac (blow). Attach the rod to my drill, turn on the vac and rod and move

in and out. When I have to put extensions on the rod, turn off the drill and

screw on next section of rod and continue.

Exhaust pipe ends up looking as good as new.

I just cut a piece of metal big enough to cover the hole, screw in four holes that I

made, and then put whatever gook you are using.

Fast, easy and does a perfect job.

I got too much time on my hands and like to look for things to be done in an easier way.

Next time you clean your vent, just unscrew the four screws, remove the piece of metal,

and go to it.....done in no time at all!!

Keep it clean....

I took my vac, put the end of the hose to the middle of the T, traced a hole a little

bigger so I could get my cleaning rod in the hole and drill a hole, put my saw

blade in and cut a hole in 15 seconds. I can now put in the brush and then the

end of the vac (blow). Attach the rod to my drill, turn on the vac and rod and move

in and out. When I have to put extensions on the rod, turn off the drill and

screw on next section of rod and continue.

Exhaust pipe ends up looking as good as new.

I just cut a piece of metal big enough to cover the hole, screw in four holes that I

made, and then put whatever gook you are using.

Fast, easy and does a perfect job.

I got too much time on my hands and like to look for things to be done in an easier way.

Next time you clean your vent, just unscrew the four screws, remove the piece of metal,

and go to it.....done in no time at all!!

Keep it clean....

Thank you for all for responding to my plea for help. I had noticed the gap in the sealant around the combustion motor, I probably did that pulling the stove out (maybe). I decided that since this joint needed work anyway to just finish pulling it off enough to pull the stove away from the clean out t. I just did that and here are pictures of what I found. Ash and lots of it. The insert actually was installed in this house by my mother. She had the stove and chimney serviced every year religiously up until she was diagnosed with dementia in 2005. I used the stove a bit last year and it was burning fine. I thought I would have it serviced this fall but money is tight so it did not get done. The first time I lit it the house filled with smoke so I knew something was wrong. I then got distracted by the pellets not feeding and assumed they had jammed over the summer in the auger. So, I spent time on that but could not get it to turn. Researching this online I found out about the pressure switch and the auger shutdown if the flue is clogged. I'm going to clean the venting out as best I can and reuse the piping (it looks okay) after I clean off all of the old sealant. I'm glad it has all been this easy, thanks to all of you!

By the way, does anyone know where I can buy the orange silicone hose to the pressure switch? Mine broke when I removed it from the motor, dry rot from age I guess. I found a place online that sells 19" for $30 but you know I only need 6 inches. Can I use another type of hose? thanks again, Debbie

By the way, does anyone know where I can buy the orange silicone hose to the pressure switch? Mine broke when I removed it from the motor, dry rot from age I guess. I found a place online that sells 19" for $30 but you know I only need 6 inches. Can I use another type of hose? thanks again, Debbie

Attachments

I

imacman

Guest

Debbie, a word of advice after seeing the new pics.......since you went to all the trouble of pulling the insert out, and getting the pipe apart, it would be very advisable to remove the combustion blower motor and clean/scrape/wirebrush the fins of the fan and the motor body, and also from what I can see built-up on the room air blower "squirrel cage" fins, that needs to be removed & cleaned as well.

Based on what I see in the pipe, the blowers can't be in great shape either. Cleaning them will greatly improve the draft of the combustion system, and give you more air into the room.

The room air blower motor, since it's an older model stove, may even have oil ports on the motor that need to be lubed.

I'd hate to see you go to all the trouble of making the pipe all nice & clean, and leave a lot of crud behind.....what my father would have called "a half-a**ed job".

You went this far....do the rest and have peace of mind.

Just my 2 cents.

PS....if you go very carefully, you can get the comb. blower gasket off w/o breaking it......go EASY, and use a sharp knife to slide between the gasket & metal housing.

Based on what I see in the pipe, the blowers can't be in great shape either. Cleaning them will greatly improve the draft of the combustion system, and give you more air into the room.

The room air blower motor, since it's an older model stove, may even have oil ports on the motor that need to be lubed.

I'd hate to see you go to all the trouble of making the pipe all nice & clean, and leave a lot of crud behind.....what my father would have called "a half-a**ed job".

You went this far....do the rest and have peace of mind.

Just my 2 cents.

PS....if you go very carefully, you can get the comb. blower gasket off w/o breaking it......go EASY, and use a sharp knife to slide between the gasket & metal housing.

festerw

Minister of Fire

Xena

Minister of Fire

thanks guys, it looks like I will have enough room to spin the stove around to get to the back to clean it out good. I was looking at the pictures and saw the ash in the room air blower. I read somewhere about pulling the combustion motor fins and cleaning them, I was worried about the gasket falling apart but I will take your advice on removal. I tapped on the flue and a lot of ash fell, almost like rocks. I'm going to get the brush and clean it out from the top also. I'd like to try that leaf blower trick but I'm a little scared of it, lol. I'll check the auto store thanks!

I

imacman

Guest

rushhourscreen said:thanks guys, it looks like I will have enough room to spin the stove around to get to the back to clean it out good. I was looking at the pictures and saw the ash in the room air blower. I read somewhere about pulling the combustion motor fins and cleaning them, I was worried about the gasket falling apart but I will take your advice on removal. I tapped on the flue and a lot of ash fell, almost like rocks. I'm going to get the brush and clean it out from the top also. I'd like to try that leaf blower trick but I'm a little scared of it, lol. I'll check the auto store thanks!

Good! And take the next step in the "tapping", and take a small hammer, and bang on the metal sides of the firebox back wall in as many places that you can.....you'll be amazed at what falls down from inside.

I don't know your stove, but does it have ash trap "doors" near the firebox that can be opened? A vacuum w/ a small rubber hose taped to it will help snake around in places you can't see or reach.

Yes, there are traps behind the fire brick. I've tried to take them off but the screws were seized and I gave up. I will do it again though, I want to give it a good cleaning now that it is out of the fireplace. That's a good idea with the rubber hose and the vacuum, I can do that with my shop vac, thanks.

I

imacman

Guest

rushhourscreen said:......I've tried to take them off but the screws were seized and I gave up. .......

Go to the auto parts store, and get a spray can of "PB Blaster" and spray the bolt/screw heads right in the beginning of the cleaning. let it soak in as long as you can.....might help break the corrosion loose.....you really need to get those ash traps open!

http://blasterchemical.com/display.cfm?p=50003&pid=4

thebubbleboy

Member

Panhandler

Minister of Fire

rushhourscreen said:Thank you for all for responding to my plea for help. I had noticed the gap in the sealant around the combustion motor, I probably did that pulling the stove out (maybe). I decided that since this joint needed work anyway to just finish pulling it off enough to pull the stove away from the clean out t. I just did that and here are pictures of what I found. Ash and lots of it. The insert actually was installed in this house by my mother. She had the stove and chimney serviced every year religiously up until she was diagnosed with dementia in 2005. I used the stove a bit last year and it was burning fine. I thought I would have it serviced this fall but money is tight so it did not get done. The first time I lit it the house filled with smoke so I knew something was wrong. I then got distracted by the pellets not feeding and assumed they had jammed over the summer in the auger. So, I spent time on that but could not get it to turn. Researching this online I found out about the pressure switch and the auger shutdown if the flue is clogged. I'm going to clean the venting out as best I can and reuse the piping (it looks okay) after I clean off all of the old sealant. I'm glad it has all been this easy, thanks to all of you!

By the way, does anyone know where I can buy the orange silicone hose to the pressure switch? Mine broke when I removed it from the motor, dry rot from age I guess. I found a place online that sells 19" for $30 but you know I only need 6 inches. Can I use another type of hose? thanks again, Debbie

The diameter of the hose is probably 1/4 inch. I buy 1/4 fuel line hose from auto parts store. They tend to harden and crack on the ends from heat. Buy a piece a few inches longer than necessary and when they start to crack you can cut off the end and reattach it. Just found the end of mine cracked and hardened yesterday (when I was cleaning) where it attaches to the combustion blower. Removed cracked end and fired it back up.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 203

- Replies

- 18

- Views

- 605

- Replies

- 3

- Views

- 343

- Replies

- 0

- Views

- 340