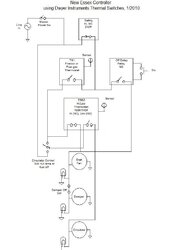

I have added a Dwyer Instrument temperature switch to my 1989 Essex boiler. The switch is used to turn the boiler off when the fuel is gone. I found that my Honeywell dual set point thermostat was ready for replacing.

I had wanted to add circulator pump start temperature on this thermostat and it would have worked but my clumsy work overstressed the contacts. Since the Dwyer Instruments worked so well in the first application and it was less expensive, I decided to switch to one of Dwyer Instruments dual set point thermal controllers. It was easy to install, just hook up power, move the switch wires from the Honeywell, and connect the temperature probe. Then using the front panel keys I could program the set points. There is a bunch of functionality, but in my case I just want to get it into service.

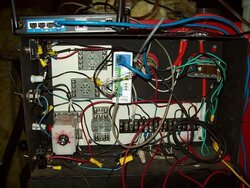

Here is a picture of the new installation, the old Honeywell part is sitting on the top, the two Dwyer Instruments switches are on the front panel, as you see they also display the current temperature.

If you are thinking about replacing your older controller parts, or adding a shutdown controller for when the fuel is gone, then here is an option to consider.

New features and data logger on next post.

I had wanted to add circulator pump start temperature on this thermostat and it would have worked but my clumsy work overstressed the contacts. Since the Dwyer Instruments worked so well in the first application and it was less expensive, I decided to switch to one of Dwyer Instruments dual set point thermal controllers. It was easy to install, just hook up power, move the switch wires from the Honeywell, and connect the temperature probe. Then using the front panel keys I could program the set points. There is a bunch of functionality, but in my case I just want to get it into service.

Here is a picture of the new installation, the old Honeywell part is sitting on the top, the two Dwyer Instruments switches are on the front panel, as you see they also display the current temperature.

If you are thinking about replacing your older controller parts, or adding a shutdown controller for when the fuel is gone, then here is an option to consider.

New features and data logger on next post.