I have struggled with my Harman Accentra-2 stove for 2 months since I got it used. The problem was constant shut downs with 6 blink error code in low demand situations. I have tried many different things, but the final thing that was actually the real cause of the problem was that my stove had the dreaded "Gummy Stove" syndrome, which caused the pellet feeder to become partially obstructed and not be able to feed pellets at a low rate.

See these threads to read all about the problems and various attempts to fix them:

https://www.hearth.com/econtent/index.php/forums/viewthread/48122

https://www.hearth.com/econtent/index.php/forums/viewthread/49226

I finally managed to fix the problem. This thread will be dedicated to describing the solution to the "Gummy Stove", so please go and read the other threads (they have pictures of what a gummy stove looks like) to learn about the problem.

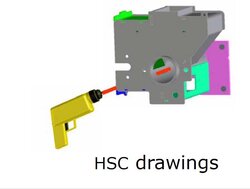

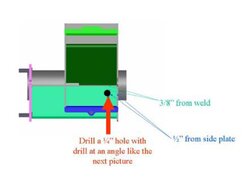

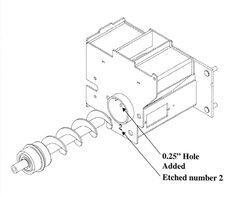

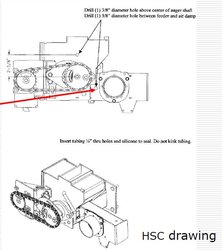

The solution had to be two fold. First order of business was to clean out the gummy build up from the feeder. Second was to modify the stove so as to prevent the build-up of gunk in the future. This problem is well known, especially in Accentra stoves. The solution has been known for a while also. A bypass tube can be added between the intake air inlet and the feeder to create an air stream from the back of the auger tube to the front thereby eliminating the combustion gas build-up in that tube.. In fact, in 2007 Harman changed the design of the feeder slightly to incorporate this solution. Harman's factory design modification achieved the same exact end as the bypass tube, but is much more simple and elegant than the tube. I will talk about this later in this post.

1. The cleaning

Cleaning the stove was more involved than the actual modification. It turns out that the gummy build-up is water soluble. So, to clean it I removed the auger and the burn pot, emptied the hopper of any pellets and made sure the pellets were gone from everywhere else I could reasonably get to in the stove. I also removed the slide plate and soaked it in hot water for an hour or so, then wiped it clean and dry. It ended up looking real clean with no traces of gummy crap left. I then used 2" plumbing test plugs I bought at Home Depot to plug up each end of the auger tube. I also stuffed a bunch of rags where the slide plate would go in. I then used an empty pellet bag that I cut up into a large piece of plastic to cover the motors and electric stuff in the back (I used masking tape to hold the plastic where I wanted it). Then I poured boiling water into the hopper and let it sit for 15-20 minutes. Then I opened the test plug at the front of the auger tube and dumped the contents into an empty container (old coffee can). I then repeated the procedure. between the first and second filling/dumping I used a toilet brush to pull through the auger tube. Then I used an old bottle brush to get into the "windows" and get more stuff out from the feeder. LOTS and LOTS of crap came out and it was stinky. I kept old towels spread out around the stove to sop up the stinky mess. It took a while, but I got all the gunk out eventually. I then let the stove sit for 24 hours before assembling to make sure that everything is dry.

Re-assembly required a new burn pot gasket ($3 at the dealer), so if you do this, make sure you have one before you start. Getting igniter wires back in was a bit fiddly, but not so bad. I used a piece of cord to push through the hole at the back all the way to the front. Then I taped (masking tape) one of the igniter wires to the cord and pulled it back with the cord. I then repeated the process for the second wire. Plugged the wires back in and put them where they belong, sealed the plug with blue RTV.

To be continued... (ran out of space)

See these threads to read all about the problems and various attempts to fix them:

https://www.hearth.com/econtent/index.php/forums/viewthread/48122

https://www.hearth.com/econtent/index.php/forums/viewthread/49226

I finally managed to fix the problem. This thread will be dedicated to describing the solution to the "Gummy Stove", so please go and read the other threads (they have pictures of what a gummy stove looks like) to learn about the problem.

The solution had to be two fold. First order of business was to clean out the gummy build up from the feeder. Second was to modify the stove so as to prevent the build-up of gunk in the future. This problem is well known, especially in Accentra stoves. The solution has been known for a while also. A bypass tube can be added between the intake air inlet and the feeder to create an air stream from the back of the auger tube to the front thereby eliminating the combustion gas build-up in that tube.. In fact, in 2007 Harman changed the design of the feeder slightly to incorporate this solution. Harman's factory design modification achieved the same exact end as the bypass tube, but is much more simple and elegant than the tube. I will talk about this later in this post.

1. The cleaning

Cleaning the stove was more involved than the actual modification. It turns out that the gummy build-up is water soluble. So, to clean it I removed the auger and the burn pot, emptied the hopper of any pellets and made sure the pellets were gone from everywhere else I could reasonably get to in the stove. I also removed the slide plate and soaked it in hot water for an hour or so, then wiped it clean and dry. It ended up looking real clean with no traces of gummy crap left. I then used 2" plumbing test plugs I bought at Home Depot to plug up each end of the auger tube. I also stuffed a bunch of rags where the slide plate would go in. I then used an empty pellet bag that I cut up into a large piece of plastic to cover the motors and electric stuff in the back (I used masking tape to hold the plastic where I wanted it). Then I poured boiling water into the hopper and let it sit for 15-20 minutes. Then I opened the test plug at the front of the auger tube and dumped the contents into an empty container (old coffee can). I then repeated the procedure. between the first and second filling/dumping I used a toilet brush to pull through the auger tube. Then I used an old bottle brush to get into the "windows" and get more stuff out from the feeder. LOTS and LOTS of crap came out and it was stinky. I kept old towels spread out around the stove to sop up the stinky mess. It took a while, but I got all the gunk out eventually. I then let the stove sit for 24 hours before assembling to make sure that everything is dry.

Re-assembly required a new burn pot gasket ($3 at the dealer), so if you do this, make sure you have one before you start. Getting igniter wires back in was a bit fiddly, but not so bad. I used a piece of cord to push through the hole at the back all the way to the front. Then I taped (masking tape) one of the igniter wires to the cord and pulled it back with the cord. I then repeated the process for the second wire. Plugged the wires back in and put them where they belong, sealed the plug with blue RTV.

To be continued... (ran out of space)