I am thinking of getting an E-180 woodgun with oil back-up and domestic coil and am wondering if there are any owners here. How many sf do you heat, what type of heating (in floor, baseboard...) wood feeding schedule, outside temps. Are you happy with it? If this is a little overkill for my needs what are the downsides of not getting the E-140?

woodgun E-180 owners

- Thread starter mark123

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

chiefburritt

New Member

Not an E180 but a E250 with steam. Ballon frame, two story, 14 rooms, 44 windows... Oh yeah steam too. Can't say enough good things about the wood gun. I love it, best thing I have ever donemark123 said:I am thinking of getting an E-180 woodgun with oil back-up and domestic coil and am wondering if there are any owners here. How many sf do you heat, what type of heating (in floor, baseboard...) wood feeding schedule, outside temps. Are you happy with it? If this is a little overkill for my needs what are the downsides of not getting the E-140?

:{)

muncybob

Minister of Fire

Also not the unit you mentioned...I have the smallest one they make heating 2100 sq ft with 2 baseboard zones. 1 zone is normally around 65 and the "main" zone is at 70 until apprx 11pm then it drops to 66 until 6:30 am.

With that said I can put in a full load 3 times per day on cold days(daytime temps in the teens) and have no problem with heat/hot water supply and plenty of coals to resatrt each fire/load. Our unit is in the basement directly below our living room and we benefit from the residual heat rising from the basement. But, we load more like 4 times a day with less than "full loads" mainly because there are other reasons we are in the basement and smaller loads seem to help keep any smoke escape down. This is mainly due to not having to raise the smoke shield very much which is something you need to do when putting in a large load.

With that said I can put in a full load 3 times per day on cold days(daytime temps in the teens) and have no problem with heat/hot water supply and plenty of coals to resatrt each fire/load. Our unit is in the basement directly below our living room and we benefit from the residual heat rising from the basement. But, we load more like 4 times a day with less than "full loads" mainly because there are other reasons we are in the basement and smaller loads seem to help keep any smoke escape down. This is mainly due to not having to raise the smoke shield very much which is something you need to do when putting in a large load.

WoodNotOil

Minister of Fire

I have heard that Wood Gun boilers do not need storage because they completely close O2 off from the fire chamber when not firing. Are users finding this to be the case?

Mark123 - Give us some specifics on sq. ft., insulation, age of construction, type of heat dist., etc. and we can probably give you more feedback on sizing.

PS - MuncyBob - thanks for adding the comment on the Wood Gun on my site. I think you may have been cut off by the character limit on that field. If so, please send me the remainder of what you intended to write and I will put it in.

Mark123 - Give us some specifics on sq. ft., insulation, age of construction, type of heat dist., etc. and we can probably give you more feedback on sizing.

PS - MuncyBob - thanks for adding the comment on the Wood Gun on my site. I think you may have been cut off by the character limit on that field. If so, please send me the remainder of what you intended to write and I will put it in.

muncybob

Minister of Fire

WoodNotOil said:I have heard that Wood Gun boilers do not need storage because they completely close O2 off from the fire chamber when not firing. Are users finding this to be the case?

Mark123 - Give us some specifics on sq. ft., insulation, age of construction, type of heat dist., etc. and we can probably give you more feedback on sizing.

PS - MuncyBob - thanks for adding the comment on the Wood Gun on my site. I think you may have been cut off by the character limit on that field. If so, please send me the remainder of what you intended to write and I will put it in.

Didn't realize it was cut off....draft fan was defeated while burning oil.

I think WG's don't need storage as much as most any other boiler but I'm sure they could benefit from it and I hope to one day be able to add storage for the convenience of 1 fire per day or so. I'm not sure but I think idling is kept to a minimum with the air cut off/reduction and perhaps that helps to reduce emissions and saves on wood consumption versus other boilers w/o storage that idle the same amount. I'll know better after this heating season based on how much wood we consume, but at this point I'm a happy camper! We have not yet hit 2 cords(since October) and the wood has been less than idealy seasoned(mostly low to mid 20% mc).

Ok here is my situation. 1300sf main area 600 sf loft 1900sf walk out basement and 2 car garage. 5 zones total, 1 loft, 1 main area, 1 for 2 bedrooms on main level, 1 basement and the garage. I am in eastern Canada. House is 5 years old well insulated A frame with side wings. I currently have a Benjamin CC 500 wood/oil boiler and use it for wood only. Wood BTU is 80000 and it will only keep up to heating the 2 bedroom zone and domestic hot water. The rest of the house not including garage and basement are kept warm by a wood stove. The boiler burns about 9 cord and the stove 2-3. The other day I switched on the oil burner few 2 days just to see what would happen and put all thermostats at 72. Then oil burn would not shut off and some zones didn't come up to temp. I then lit the wood as well and everything came up to temp. The oil puts out approx. 110000 BTU. The garage and basement are in floor radiant and the other zones are pex in flor joist cavity with R-12 fiberglass under pipes. I was talking to someone nearby that has 3800sf plus basement and has the E-180 no storage and burn 12 cord/year and keeps the house very warm and boiler is 75 feet from house. I don't have room for a seperate oil boiler so that is why I like the built in oil burner of the woodgun. Thanks for any opinions

WoodNotOil

Minister of Fire

The 140 is probably more in your size range if I had to guess. I am not sure what the effect would be if it had to idle a lot because it was oversized. I would talk to the folks you are buying it from about that.

tbsdolmar

New Member

One thing you need to ask is how much the center bricks cost and how much it is to replace the refractory. I hooked up an E-100 for a customer and he found out that the center bricks were around $134 and he had to replace them after 1 year. His refractory had some erosion in it after 1 year also. I have heard that the refractory is around $1200. I think they tell you that the center bricks should last 16 cords and the refractory 6-10 years. This was the main reason I bought the Biomass. The whole refractory costs $150 and Zenon warrants it for 5 years.

muncybob

Minister of Fire

The Wood Gun manual states center bricks should last 10 to 15 cords and larger refractory should last 10-15 years. This is a maintenance item I had not considered when looking at various boilers. If I get 15 years on the larger I'll be happy but I would have thought the "nozzle" brick should last longer than 10 cords!

tbsdolmar

New Member

This guy only burnt 6 cords of wood last year. He said if he had known what he knows now he probably would not have gotten it. And like I said he already has erosion in the large refractory, so who knows how long it will last. I'm just pointing out some things that most people don't take into consideration when buying these. This stuff can add up over the years.

Has anyone here made there own refractories, The center ones for the wood gun look pretty simple, it would not be hard to make a mold, maybe from fiberglass and then mix your own refractory cement such as this. I think there is stainless mesh in there as well.

http://www.backyardmetalcasting.com/refractories.html

http://www.backyardmetalcasting.com/refractories.html

chiefburritt

New Member

tbsdolmar said:One thing you need to ask is how much the center bricks cost and how much it is to replace the refractory. I hooked up an E-100 for a customer and he found out that the center bricks were around $134 and he had to replace them after 1 year. His refractory had some erosion in it after 1 year also. I have heard that the refractory is around $1200. I think they tell you that the center bricks should last 16 cords and the refractory 6-10 years. This was the main reason I bought the Biomass. The whole refractory costs $150 and Zenon warrants it for 5 years.

Soooo! Call the local boiler guy to service the oil burner and you'll pay at least ,your quote $134, buy the oil at whatever the speculators set it at, pay the tax on the oil. it doesn't matter if i have to buy a set of center bricks once a year, big deal I'm still ahead of the game. Everything has a maintenance cost, nothing is perfect. Especially if man made it. Not arguing with you but that is the way of life. My woodgun operates as advertised and I am very pleased with that, it's what makes me happy.

BTW they are the only manufacturer that would do a steam application, so. You gotta remember you are burning with wood it takes work and some maintenance to make it all worth it.

sbleiweiss

New Member

The E140 and E180 are about the same BTU output, the main difference is the firebox volume. The boiler part number is not exactly the BTU rating.

Part # Output Firebox (Cu Ft)

E100 100K 6.5

E140 140K 10

E180 150K 14

E200 185K 18

E250 230K 22

The E140 and E180 are the same length. I believe this roughly sets the BTU output with any other difference coming from the amount of air pulled through the unit. I think the E180 has the belt drive fan set-up where the E140 is direct drive. The belt drive fan keeps the motor away from the heat and should allow the bearings to last much longer. I think this is a better setup as it allows some adjustment of fan speed to adjust for your type of wood. All units up to the E180 are 6" flue, then it's 8".

The BTU load described by Mark has me a bit concerned if the E140-E180 size boiler will meet the needs. The listed output numbers are just a ball park in my experience. There are too many variables to know exactly what the boiler output is going to be. In my case, I burn 1 load (3.8 cu Ft estimated) of wood per day which gets me about 300k BTU into storage and another 70k BTU stranded in the boiler that I can partially recover. After initial warm-up (about an hour) it takes an additional 3+ hours to heat storage, so roughly 100K btu/hr is delivered with some heat lost directly from the boiler to the surrounding air.

Slight adjustments to the boiler and / or wood quality can vary the available BTU's a bunch, and if the boiler is running full tilt, it can burn down a load of fuel in a few hours.

Part # Output Firebox (Cu Ft)

E100 100K 6.5

E140 140K 10

E180 150K 14

E200 185K 18

E250 230K 22

The E140 and E180 are the same length. I believe this roughly sets the BTU output with any other difference coming from the amount of air pulled through the unit. I think the E180 has the belt drive fan set-up where the E140 is direct drive. The belt drive fan keeps the motor away from the heat and should allow the bearings to last much longer. I think this is a better setup as it allows some adjustment of fan speed to adjust for your type of wood. All units up to the E180 are 6" flue, then it's 8".

The BTU load described by Mark has me a bit concerned if the E140-E180 size boiler will meet the needs. The listed output numbers are just a ball park in my experience. There are too many variables to know exactly what the boiler output is going to be. In my case, I burn 1 load (3.8 cu Ft estimated) of wood per day which gets me about 300k BTU into storage and another 70k BTU stranded in the boiler that I can partially recover. After initial warm-up (about an hour) it takes an additional 3+ hours to heat storage, so roughly 100K btu/hr is delivered with some heat lost directly from the boiler to the surrounding air.

Slight adjustments to the boiler and / or wood quality can vary the available BTU's a bunch, and if the boiler is running full tilt, it can burn down a load of fuel in a few hours.

Singed Eyebrows

Minister of Fire

I'm not sure you even need to make a mold. These are probably standard size firebrick & you could drill them with the proper diamond size hole saw, just keep working the saw down till the slot is the right length. You can buy the casting material from Firebrick Engineers this is reasonable in price. For $1200 I would cast the large pieces, Randymark123 said:Has anyone here made there own refractories, The center ones for the wood gun look pretty simple, it would not be hard to make a mold, maybe from fiberglass and then mix your own refractory cement such as this. I think there is stainless mesh in there as well.

http://www.backyardmetalcasting.com/refractories.html

The bricks I saw for the woodgun 140 are trapazoidal about 3-4" wide at top and

2-3 " at bottom, about 1.5" thick and around 15" long with elongated holes though them. Here is another pages about a guy who made his own for a woodstove.

http://www.gordosoft.com/woodstove/refractoryDIY.htm

2-3 " at bottom, about 1.5" thick and around 15" long with elongated holes though them. Here is another pages about a guy who made his own for a woodstove.

http://www.gordosoft.com/woodstove/refractoryDIY.htm

sbleiweiss

New Member

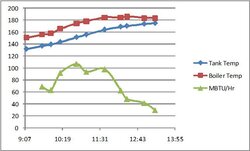

I had a chance yesterday to measure boiler output by tracking how quickly it heated storage. During this cycle there was no call for heat from the house. This is my normal burning method which aims to economize wood and not to max out boiler output. I was using some very well seasoned oak, loading 1/2 initially, with 1 reload about 1/2 way through the burn and letting it burn down to coals (because I plan to clean it today). I am sure this boiler could hit rated output by adding all the wood at once and giving it more air. This run was with the air damper just a tiny bit open.

Attachments

Fred61

Minister of Fire

muncybob said:The Wood Gun manual states center bricks should last 10 to 15 cords and larger refractory should last 10-15 years. This is a maintenance item I had not considered when looking at various boilers. If I get 15 years on the larger I'll be happy but I would have thought the "nozzle" brick should last longer than 10 cords!

Fred61 said:The WOOD GUN convinced me that wood gassification was the only way to heat with wood but it had some issues. It would eat up it’s insides in one heating season. I found myself paying more to replace ceramic nozzles ,door seals and other refractories each Spring than it would have cost me to heat with oil. It did have one featrure that was great! A motorized inlet flap. Never overheated nor made much creosote. Only a small amount in the loading chamber. However unless I used a good firewood that “coaled up” well the fire would not restrart after long idle time. Ran it for ten years and then sent it to the scrap heap.

A little bit of advice that may have been overlooked!

WoodNotOil

Minister of Fire

This burning up of refractory seems like a design flaw. I am on my 5th heating season with my Tarm and nothing has had to be replaced. I have noticed nothing so far to do with erosion of anything to do with the nozzle or anything in the path of the gasification flame. I know some of this will have to be replaced during the life of the boiler, but not very often and I seem to remember the prices I saw on the stuff was only a couple hundred at worse. I know that some other boiler manufacturer's stress in their promo materials that they use standard refractory blocks so that replacments are easy to acquire and inexpensive.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 433

- Replies

- 16

- Views

- 5K

- Replies

- 12

- Views

- 3K