Hi,

This is my first post on hearth.com, so a bit of an introduction is probably in order. My name is Joe, I live in central Maine with my wife in our 1200 sq ft two story home. I am a web developer at a local PR firm, and my wife is a teacher. I love cutting wood and working on cars, small engines and electronics.

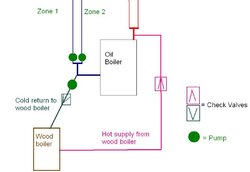

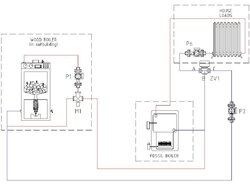

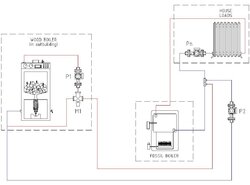

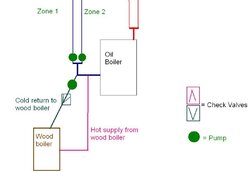

Our current house has an oil fired boiler setup that takes care of our dhw and baseboard heat. My father in law is giving me an old 1978 Memco mw100 that I will be putting in an insulated shed 30' from the house and running like an outdoor wood boiler. I'm planning on using a 20-30 plate heat exchanger and Grundfos 3spd pump to handle the hydronics hookup to the existing system. The pump will run 24/7 like most outdoor wood boilers are set up.

Anyone else running Memco boilers? What are you guys getting for run time? Do I need water storage? The water jacket is only 50 gallons, which is quite low compared to newer boilers that seem to have 150gallons as a minimum. How tall do I need to make my chimney?

It looks like this forum should provide lots of useful info and tips from the bit of digging around I've done so far.

Thanks!

This is my first post on hearth.com, so a bit of an introduction is probably in order. My name is Joe, I live in central Maine with my wife in our 1200 sq ft two story home. I am a web developer at a local PR firm, and my wife is a teacher. I love cutting wood and working on cars, small engines and electronics.

Our current house has an oil fired boiler setup that takes care of our dhw and baseboard heat. My father in law is giving me an old 1978 Memco mw100 that I will be putting in an insulated shed 30' from the house and running like an outdoor wood boiler. I'm planning on using a 20-30 plate heat exchanger and Grundfos 3spd pump to handle the hydronics hookup to the existing system. The pump will run 24/7 like most outdoor wood boilers are set up.

Anyone else running Memco boilers? What are you guys getting for run time? Do I need water storage? The water jacket is only 50 gallons, which is quite low compared to newer boilers that seem to have 150gallons as a minimum. How tall do I need to make my chimney?

It looks like this forum should provide lots of useful info and tips from the bit of digging around I've done so far.

Thanks!