Hi all, hope everyone East of the Divide is warm tonight, 'cause it got cold again up here. Here's my question(s).

- First, a short backgound on this thing. Stove is a "Timberline", kind of a Fisher knock-off. Big, plate steel, solid cast doors. Air controls consist of two knobs, one on each door.I've put a rope gasket on the stove, and the doors seal well at this point. I've also added secondary air. For what it's worth, I burn Pine exclusivly, and get pretty decent burn times with my set-up.(The BKK may be on hold for awhile). BUT, I want some glass on this stove.

-1- I've ruled out modifying the cast doors, due to potential cracking issues, and am going to build a single door out of plate steel and glass.

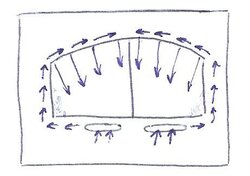

-2- I want to have an air-wash feature, and eliminating the cast doors also eliminates my air controls,soooo how should I go about this? There is enough room between the step-top of the stove and the doors, to build an adjustable air intake, but this would mean very little pre-heating.

-3- Is pre-heating the incoming air supply critical?

These questions really only apply to keeping the glass clean and not subject to thermal shock. Anybody try this? Thanks, John.

- First, a short backgound on this thing. Stove is a "Timberline", kind of a Fisher knock-off. Big, plate steel, solid cast doors. Air controls consist of two knobs, one on each door.I've put a rope gasket on the stove, and the doors seal well at this point. I've also added secondary air. For what it's worth, I burn Pine exclusivly, and get pretty decent burn times with my set-up.(The BKK may be on hold for awhile). BUT, I want some glass on this stove.

-1- I've ruled out modifying the cast doors, due to potential cracking issues, and am going to build a single door out of plate steel and glass.

-2- I want to have an air-wash feature, and eliminating the cast doors also eliminates my air controls,soooo how should I go about this? There is enough room between the step-top of the stove and the doors, to build an adjustable air intake, but this would mean very little pre-heating.

-3- Is pre-heating the incoming air supply critical?

These questions really only apply to keeping the glass clean and not subject to thermal shock. Anybody try this? Thanks, John.